לפרויקטים מקצועיים בתחום הקישוט והצגה יש צורך בחומרים איכותיים שיספקו תוצאות עקביות ועמידות לאורך זמן. בבחירת לוחות חיתוך לא חתוכים למשרדי אומנות, תצוגות צילום או יישומים מסחריים של קישוט, הבנת התכונות המרכזיות ואפשרויות הספקה הופכת לנחוצה להשגת תוצאות ברמה מקצועית. לוח חיתוך איכותי משמש כבסיס לשימור יצירות אומנות, תמונות וממסכים חשובים, תוך שיפור ההתרשמות החזותית באמצעות התאמת צבעים מדויקת ותמיכה מבנית.

שוק חומרי תוספת פרימיום התפתח בצורה משמעותית, ומציע מגוון אפשרויות החל מלוחות מוזיאון באיכות שימור ועד לחלופות כלכליות המתאימות לדרישות פרויקט שונות. צורפי מסגרות מקצועיים, אמנים וחובבים מכירים בהדרגה את חשיבות רכישת לוחות תוספת לאחתרים מספקים מוכרים שמתחזקים סטנדרטים מחמירים של בקרת איכות ומספקים مواصفات מוצר מקיפות. הבנת דינמיקות השוק מאפשרת החלטות קנייה מושכלות המתאימות לצרכים ספציפיים של הפרויקט ולשקולות התקציב.

הבנת הרכב לוח התוספת וסטנדרטי האיכות

בניית חומר הליבה

קרטון מתכוון פרימיום, שאינו חתוך, מורכב לרוב ממספר שכבות של חומרים שנבחרו בקפידה, אשר נועדו לספק יציבות מבנית ועמידות ארכיונית. הבנייה הפנימית כוללת לעתים קרובות סיבי כותנה או פulp עץ איכותי שעובד כדי להסיר ליגנין ותרכובות חומציות אחרות שיכולות לפגוע בשימור לאורך זמן. בחירה meticulous בחומרים מספקת יציבות ממדית ושימור צבע לאורך תקופות ממושכות, מה שהופך את הקרטון המתכוון ללא חתוך מתאים ליצירות אמנות יקרות ולמסמכים חשובים.

תהליכי הייצור של לוחות מתכת לא גזורים באיכות גבוהה כוללים בקרה מדויקת של רמת הלחות, אחידות הצפיפות ואיפיון עקבי של משטח הפנים. מתקני ייצור מתקדמים משתמשים בצORים מיוחדים כדי להשיג סיבובים עקביים של עובי ומאפייני חיתוך חלקים שדרושים על ידי מסגרים מקצועיים. המוצר המתקבל מציג איכות קצה מרשימה לאחר החיתוך, תוך מינימום של קריעות או משטחים מחוספסים שעלולים לפגוע בהצגה הסופית.

תכונות ארכיוניות ותקני שימור

לוחות מתכת לא גזורים בדרגת שימור עומדים בתקנים ארכיוניים חמירים כפי שנקבעו על ידי אנשי מקצוע בתחום שימור של מוזיאונים וספריות. דרישות אלו כוללות ניטרליות pH, הרכב ללא ליגנין, ועמידות בפני גורמים סביבתיים כגון תנודות רטיבות וחשיפה לאור אולטרה-סגול. יצרנים איכותיים מבצעים בדיקות תקופתיות כדי לוודא שהמוצרים שלהם שומרים על מאפייני השימור הקריטיים הללו לאורך כל חיי המדף.

חשיבותה של איכות ארכיון בולטת במיוחד בעבודות שימור מקצועיות, בהן לוח מתאר לא חתוך נמצא במגע ישיר עם יצירות אומנות יקרות או מסמכים היסטוריים. חומרים לא תקניים עלולים להכיל תרכובות חומציות או צבעים לא יציבים שעלולים לעבור לחומרים סמוכים לאורך זמן, מה שעלול לגרום לנזק בלתי הפיך. מוצרים מקצועיים עוברים בדיקות בקרת איכות קפדניות כדי להבטיח שהם עומדים בדרישות או עולות על תקני התעשייה בתחום היציבות הארכיבונית.

בחירת צבע והיבטים אסתטיים

תבליטי צבע סטנדרטיים

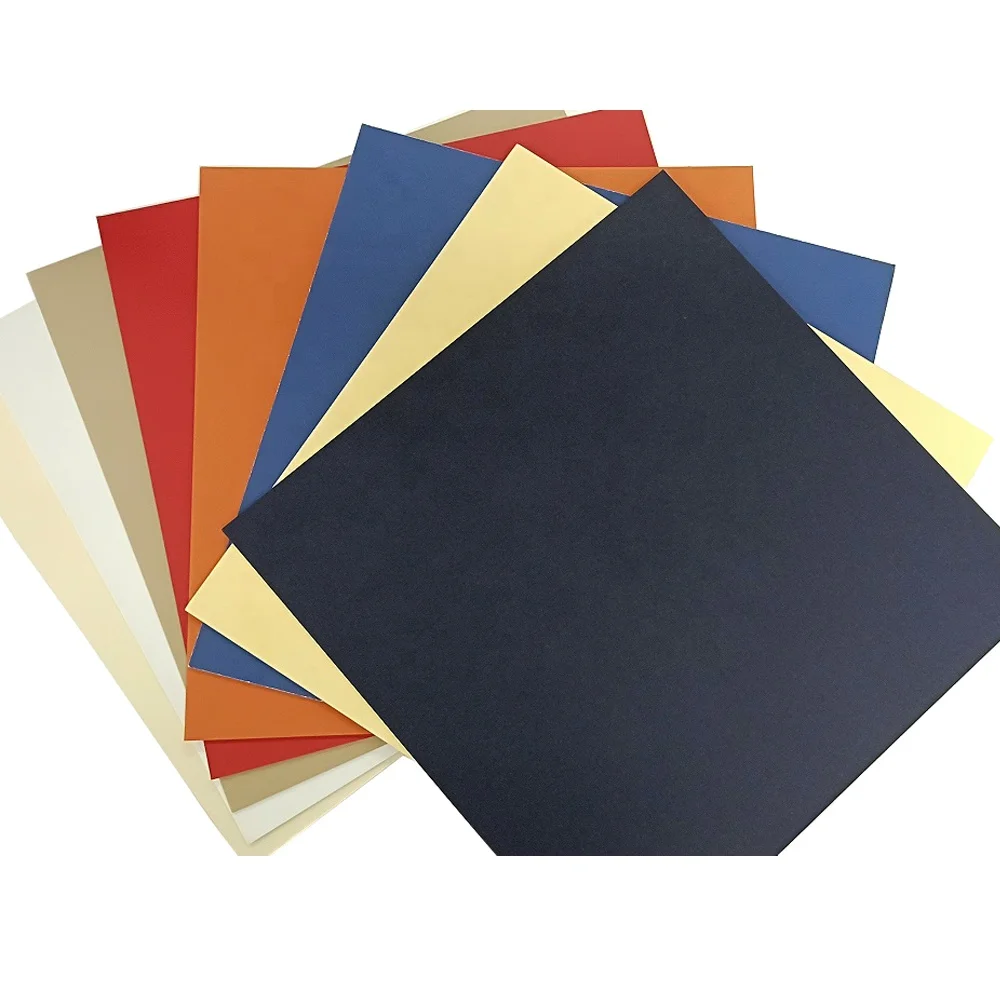

ספקים איכותיים מציעים מגוון רחב של צבעים במוצרים שלהם לוח מסגרה לא חתוך מלאי, החל מצבעים ניטרליים קלאסיים ועד צבעים מיוחדים בוהקים שמשלימים סגנונות אומנותיים מגוונים ודרישות הצגה. ההצעות הסטנדרטיות כוללות לרוב גוונים שונים של לבן, קרם וגוון אפור שמספקים אפשרויות רב-שימושיות למרבית יישומי התצורה. צבעים אלו נשמרים זמינים באופן עקבי ומאפיינים ביצועים מוכחים שעליהם מסתמכים צורפי מסגרות מקצועיים בפרויקטים השוטפים שלהם.

תכניות צבעים מיוחדות מתרחבות מעבר לפלטות בסיסיות וכוללות גווני אבן יקרה עשירים, צבעי אדמה וגוונים מודרניים של מעצבים שמשקפים מגמות אסתטיות עכשוויות. יצרנים פרימיום משקיעים במערכות צביעה מתקדמות שמביאות לשיעור עמידות לאור ואילחוס צבע יוצא דופן, מה שמונע מהקרטון את האפשרות לשמור על המראה המיועד לאורך כל תקופת השימוש. מחויבות זו לשמירתות הצבע היא חיונית ליישומי הצגה איכותיים שבהם עקביות אסתטית ארוכת טווח היא בעלת חשיבות עליונה.

התאמת צבעים ותיאום

בפרויקטים מקצועיים של מסגרות יש צורך לעיתים קרובות בהתאמת צבעים מדויקת בין לוחות תשתית לא חתוכים לבין היצירה או התמונות המוצגות. ספקים בעלי ניסיון מספקים שירותי התאמת צבעים מקיפים ומחזיקים מערכות ייחוס מפורטות של צבעים המאפשרות בחירה מדויקת בתנאי תאורה שונים. תשומת לב זו להצגת הצבעים במדויק עוזרת להבטיח שההצגה הסופית ת log את ההשפעה החזותית הרצויה וההרמוניה האסתטית.

מערכות ניהול צבעים מתקדמות שמשתמשות בהן יצרניות איכותיות משתמשות בפרוטוקולי מדידת צבע סטנדרטיים שמובילים לעקביות בין דפנות ייצור. גישה שיטתית זו לשליטה בצבע מפחיתה עד כמה שניתן את השוני שעלול להשפיע על פרויקטים הדורשים מספר גיליונות של לוחות תשתית לא חתוכים או לצורך החלפה בעתיד. משתמשים מקצועיים מחמיאים במיוחד לעקביות זו בתקנות מסחריות ובסדרות פרויקטים מתמשכות.

אפשרויות ממדים וمواصفות מימדיות

מימדי גיליון סטנדרטיים

ספקים איכותיים של לוחות מטריה לא חתוכים מציעים בדרך כלל אפשרויות מגוונות של מידות שמתאימות לצרכים של פרויקטים שונים, החל מקופסאות הצגה קטנות ועד להצגות ארכיטקטוניות גדולות. מידות הגיליונות הסטנדרטיות כוללות גדלים נפוצים כגון 20x30 אינץ', 32x40 אינץ', וכן אפשרויות בפורמטים גדולים יותר עד 40x60 אינץ' או לפי דרישות מותאמות. מגוון המידות הזה מספק גמישות בשימוש יעיל בחומר ובתכנון פרויקטים, תוך מינימום של פסולת בתהליכי תצורה מקצועיים.

מפרטים של עובי ללוחות מט ללא חיתוך באיכות גבוהה נעים בדרך כלל בין 4-שכבות ל-8-שכבות, כאשר כל ציון של שכבה מציין עובי של כ-1/16 אינץ' של החומר. ביישומים מקצועיים מעדיפים לרוב אפשרויות של 4 או 6 שכבות שמספקות תמיכה מבנית מספקת, תוך שמירה על עלות סבירה וקלות בחיתוך. יישומים מיוחדים עשויים להידרש לגירסאות עבות יותר שמציעות יציבות מימדית משופרת להצגות בתבנית גדולה או בתנאים סביבתיים קשים.

מימדים בהתאמה אישית והזמנות מיוחדות

ספקים מקצועיים מבינים שפרויקטים מסוימים דורשים מידות מותאמות אישית מעבר למימדי הגיליונות הסטנדרטיים, במיוחד ליישומים ארכיטקטיים, התקנות מוזיאונים או מצגות מסחריות מיוחדות. יצרנים איכותיים שומרים על יכולת ייצור של לוחות תשתית לא גזורים בגדלים מותאמים אישית, תוך שמירה על مواصفות החומר ותקני האיכות של הצעות הסטנדרטיות שלהם. גמישות זו מאפשרת למסגרים מקצועיים להתמודד עם פרויקטים ייחודיים מבלי להקריב את איכות החומר או הביצועים.

זמני מוביל עבור הזמנות לוחות תשתית לא גזורים מותאמים משתנים בהתאם לדרישות הספציפיות וללוח הזמנים של הייצור, אך ספקים מוכרים שומרים בדרך כלל על תהליכים יעילים הממזערים עיכובים בפרויקטים רגישים לזמן. תקשורת ברורה בנוגע לסובלנות ממדידה, דרישות סיום הקצוות וمواصفות אריזה עוזרת להבטיח שההזמנות המותאמות יתאימו בדיוק לצרכים של הפרויקט בעת המסירה.

אסטרטגיות רכש ליישומים מקצועיים

קריטריוני הערכת ספקים

בחירת ספקים אמינים ללוחות לא חתוכים מחייבת הערכה זהירה של גורמים רבים מעבר לשקולות מחיר בסיסיות. קונים מקצועיים מעריכים את יכולות הספק, כולל עומק מלאי, עקביות באיכות, אמינות במשלוח ושירותי תמיכה טכנית. ספקים מוכרים מדגימים את מחויבותם לאיכות באמצעות תיעוד מוצרים מקיף, אישורי חומרים ושירות לקוחות תואם שפותר שאלות טכניות והנחיות יישום.

תכניות הבטחת איכות שמיושמות על ידי ספקים מוכרים כוללות בדיקת חומרים בהגעה, ניטור ייצור ובדיקות של מוצרים גמורים כדי להבטיח מאפייני ביצועים עקביים. גישות שיטתיות אלו לשליטת איכות מספקות ביטחון שמשלוחי לוחות לא חתוכים יתאימו לדרישות המצוינות וייבחנו בצורה אמינה ביישומים קפדניים. משתמשים מקצועיים נהנים מספקים שמתחזקים רשומות איכות מפורטות ויכולים לספק את האפשרות לעקוב אחר ממוצרי הספק.

רכישה בכמויות גדולות וניהול מלאי

פעולות תצורה מקצועיות נוטות להשיג יתרונות משמעותיים עלות באמצעות רכישת ערך נפחית של לוחות חתך לא גזורים, תוך שמירה על רמות מלאי מתאימות לתמיכה בדרישות הייצור המתמשכות. ניהול מלאי יעיל מאזן בין היתר של דיסקונטים לרכישות בכמויות גדולות מול עלות האחסון ושקולים הקשורים לתקופת התפוגה של החומרים. ספקים איכותיים תומכים באסטרטגיות אלו באמצעות תכניות הזמנה גמישות, לוחות משלוחים צפויים וסיוע בניהול המלאי.

הקמת יחסים לטווח ארוך עם ספקים מהימנים של לוחות חומרה לא גזוזים מאפשרת למת framing מקצועיים לנהל משא ומתן על תנאים מועדפים בנוגע למחירים, הקצאת עדיפות לצבעים וגדלים בעלי ביקוש גבוה, והודעה מוקדמת על הצגת מוצרים חדשים. שراויות אלו הופכות לחשובות במיוחד בעונות שיא או כאשר נדרשים חומרים מיוחדים לפרויקטים חשובים. יחסים עקביים עם הספקים מקלות גם על תקשורת טובה יותר בנושאי איכות, مواصفות טכניות ותמיכה ביישום.

הערכת איכות ושיטות בדיקה

הערכת תכונות פיזיות

הערכת איכות מקצועית של לוחות חומר גולמי כוללת הערכה שיטתית של תכונות פיזיות, כולל חלקות פני השטח, איכות הקצוות, יציבות ממדים ותקינות המבנית. בדיקה ויזואלית חושפת פגמים בשטח, עקביות צבע ואיכות ייצור כללית שעלולה להשפיע על ביצועי החיתוך או המראה הסופי. הערכה טקטילית מספקת תובנות בנוגע לצפיפות החומר, גמישותו ומאפייני הקצה, אשר משפיעים על דרישות העיבוד ואיכות ההצגה הסופית.

שיטות בדיקה מתקדמות שמשתמשים בהן ספקים בעלי דרישות איכות גבוהות כוללות מדידת תכולת הלחות, בדיקות pH ומחקרים של הشيخנות מאיצה שמנבאים את התכונות של הביצועים לאורך זמן. גישות מדעיות אלו להערכת איכות מספקות נתונים אובייקטיביים התומכים בדרישות החומר ובהצהרות על הביצועים. משתמשים מקצועיים נהנים מספקים שמשתפים את תוצאות הבדיקות ושומרים על דוקומנטציה שקופה של איכות למוצרי לוחות הקטן לא חתוכים.

אימות ביצועים ביישום

הערכת ביצועים בעולם האמיתי של לוח קטנות לא חתוך מתבצעת באמצעות ניטור זהיר של תכונות חיתוך, איכות השפה והיציבות לאורך זמן בפריסופים מסודרים. צונחים מקצועיים פותחים פרוטוקולי הערכה המעריכים כיצד חומרים שונים מתנהגים תחת ציוד החיתוך הספציפי שלהם והתנאים הסביבתיים שבהם הם פועלים. ניסיון מעשי זה מספק משוב יקר להחלטות בתחום בחירת הספקים ודרישות החומר.

תיעוד ביצועי החומר לאורך זמן מאפשר למשתמשים מקצועיים לבנות מסדי נתונים מקיפים של ספקים ואמינות מוצרים. המבט ההסטורי הזה חשוב להחלטות רכישה מושכלות ולזיהוי חומרים שמספקים תוצאות עיליות באופן עקבי. ספקים איכותיים מתייחסים למשוב זה בברכה ומשתמשים בו לשיפור מתמיד בתהליכי הייצור של לוחות מט חסרי חיתוך ובהגדרות המוצר.

שיקולים כלכליים וניתוח ערך

הבנת מבנה המחירים

רכש מקצועי של לוחות חומר לא גזורים דורש הבנה מקיפה של מבני מחירים שיכולים להשתנות בהתאם לכמות, בחירת צבע, מפרט מידות ודרישות משלוח. חומרים איכותיים מסוג שימור לרוב מציבים מחירים גבוהים יותר, אך מספקים מאפייני ביצועים ויציבות ארכיונית עליונים המצדיקים את ההשקעה ביישומים קריטיים. פרויקטים שמתמקדים בתקציב יכולים להשתמש באפשרויות דרגת סטנדרט שמציעות ביצועים מספיקים ליישומים שאינם ארכיוניים ובמחיר מופחת.

הנחות כמותיות לקניית לוחות מט לא חתוכים מספקות לעיתים קרובות חיסכון משמעותי בעלויות עבור אמני תצורה מקצועיים שמתחזיקים דפוסי שימוש עקביים בחומרים. הבנת נקודות השבירה של רמות תמחור שונות מאפשרת החלטות קנייה אסטרטגיות שממזערות את עלות החומרים תוך שמירה על רמות מלאי מספקות. ספקים איכותיים מספקים מידע תמחור שקוף ופועלים עם לקוחות מקצועיים כדי לזהות אסטרטגיות הזמנה אופטימליות המאזנות בין שיקולי עלות לדרישות תפעוליות.

ניתוח석 של עלות ההחזקה הכוללת

ניתוח עלות מקיף עבור לוחות תשתית לא גזורים מתרחב מעבר למחיר הקנייה הראשוני וכולל גורמים כגון תשואה מקutting, שיעורי פסול, יעילות עיבוד, ואמינות ביצועים לאורך זמן. חומרים פרימיום מציגים לעתים קרובות מאפייני cutting מוכחים שמפחיתים את כמות הפסול ומשפרים את יעילות העיבוד, ובכך יכולים לפצות על העלויות הראשוניות הגבוהות יותר באמצעות שיפור בהספק ובה wykorzystanie החומר.

עלותים נסתרות הקשורות לאיכות נמוכה של לוחות מת לא חתוכים עשויות לכלול שיעורי ביזבוז מוגברים, קשיי עיבוד, תלונות לקוחות ודרישות אפשריות לעבודה מחדש. ציירים מקצועיים מודעים באופן גובר לערכה של השקעה בחומרים איכותיים שמפחיתים את הקשיים התפעוליים הללו ותומכים בייצור עקבי של מוצרים סופיים באיכות גבוהה. נקודת המבט הזו של עלות כוללת מדריכה את החלטות בחירת החומרים שמאפשרות אופטימיזציה הן של עלויות הפרויקט הנוכחי והן של יעילות תפעולית ארוכת טווח.

שאלות נפוצות

איזו עובי של לוח מת לא חתוך הוא הטוב ביותר למסגרת תמונות סטנדרטית

עבור רוב יישומי תצוגה סטנדרטיים, לוח מתאם לא חתוך בגודל 4-ply מספק שיוויון מצוין בין תמיכה מבנית, קלות ביצוע חיתוך ויעילות עלות. עובי זה, בערך 1/16 אינץ', מספק קשיחות מספקת לגודלי מסגרות טיפוסיים, תוך כדי שהמוצר נשאר קל לחיתוך באמצעות ציוד תצוגה סטנדרטי. מארזים מקצועיים נוטים לאחסן את ה-4-ply כעובי ראשי, ולהשתמש באפשרויות עבות יותר כמו 6-ply או 8-ply להצגות גדולות יותר או כאשר נדרשת יציבות ממדית משופרת.

איך יש לאחסן לוח מתאם לא חתוך כדי לשמור על האיכות

אחסון תקין של לוחות מט מראשيتם מחייב שמירה על תנאי טמפרטורה ורطوبة קבועים, בדרך כלל בין 65-75°F עם רטיבות יחסית של כ-45-55%. החומרים יש לאחסן בשטח, בסביבה נקיה ויבשה, הרחק מאור שמש ישיר וממזהמים פוטנציאליים. ספקים מקצועיים ממליצים לשמור את הגיליונות באריזה המקורית עד לשימוש, ולתכנן סיבוב מלאי לפי עיקרון ראשון נכנס - ראשון יוצא, כדי להבטיח טריות ותכונות ביצועים אופטימליות.

מה ההבדלים המרכזיים בין לוח מט מראשית למדרגת שימור לבין לוח מט מראשית סטנדרטי

לוח מתכת איכותי לשימור, לא גזור, בעל הרכב חסר ליגנין, מאפיינים ניטרליים ב-pH ויציבות ארכיונית משופרת, מעוצב לשם שימור יצירות אומנות ומסמכים בעלי ערך. החומרים המובחרים עוברים בדיקות קפדניות כדי להבטיח שהם עומדים בתקני שימור איכות מוזיאון ולא יתרמו להתדרדרות לאורך זמן. דרגות סטנדרטיות עשויות להכיל טחנת עץ או חומרים אחרים שמאפשרים ביצועים סבירים ליישומים זמניים או לא ארכיוניים ובמחיר מופחת.

האם ניתן להזמין לוח מתכת לא גזור בצבעים או מידות מותאמים אישית

רוב הספקים המקצועיים מציעים התאמה של צבעים מותאמים אישית ושרותי מידה מיוחדים ללוחות חומרה לא גזורה, אם כי בדרך כלל חלות כמויות הזמנה מינימליות וזמני מוביל ארוכים יותר. צבעים מותאמים אישית דורשים הליכות ייצור מיוחדות ועשויים לכלול עמלות הכנה, בעוד שמידות מותאמות אישית תלויות ביכולות הייצור ובזמינות החומרים. רammers מקצועיים צריכים לדון בדרישות ספציפיות עם הספקים בהתחלה בתכנון הפרויקט כדי להבטיח יישום והourg מתאימים להזמנות מותאמות אישית.