עולמו של תפריט התצלומים התפתח בצורה משמעותית, וביצוע הבחירה הנכונה של לוח מתאם חתוך מראש נשארת החלטה חשובה הן למתקנים מקצועיים והן למשתמשים מחוברים בדרמה. הבנת ההבדלים העדינים בבחירת לוח מתאם חתוך מראש יכולה להפוך תמונה או יצירה רגילה ליחידה מרשימה שמאחזרת תשומת לב ושומרת על זיכרונות לאורך דורות. אפשרויות לוח מתאם חתוך מראש מודרניות מציעות נוחות חסרת תקדים תוך שמירה על תקני איכות שדורשים מתקנים מקצועיים.

הבנה לוח מסגרת חתוך מראש יסודות

מבנה ליבה וחומרים

קרטון תצורה מקוצץ מראש ברמה מקצועית מורכב ממספר שכבות שנועדו לספק יציבות מבנית וערכה אסתטי. החומר המרכזי קובע את אורך החיים, ואפשרויות חסרות חומצה מציעות מאפיינים ארכיוניים מוכרים שמניעים התחלקות וירידה באיכות לאורך זמן. הבנת אלמנטים אלו של הבנייה עוזרת לקונים לקבל החלטות מושכלות בעת השוואת מוצרי קרטון תצורה מקוצצים שזמינים בשוק התחרותי של ימינו.

kếtextורות פני השטח משתנות במידה רבה בין אפשרויות של קרטון תצורה מקוצץ, החל ממצעים חלקים שמשלימים יצירות אומנות עכשוויות וכלה במצעים בעלי kếtקסטורה שמעצימים צילומים טרדיציוניים. זווית החיתוך המוטה, שמתוחזקת בדרך כלל ב-45 מעלות, יוצרת את הקו הצללי המאפיין שמוסיף עומק ועניין ויזואלי ליצירות מסגרות. יצרני קרטון תצורה מקוצץ איכותיים מבטיחים זווית מוטה עקביות לאורך כל תהליך הייצור שלהם.

גדלים סטנדרטיים והתאמה

מימדי לוח מוכן סטנדרטיים עוקבים אחר קונבנציות מוסכמות בתחום הצילום והאמנות, מה שמקל על הבחירה בגדלי מסגרות נפוצים. הגדלים הפופולריים ביותר כוללים לוחות 8x10 עבור תמונות בגודל 5x7, לוחות 11x14 עבור צילומים בגודל 8x10, ולוחות 16x20 עבור יצירות אמנות בגודל 11x14. הבנת היחסים הפרופורציונליים האלה מבטיחה התאמה נכונה ותוצאה מקצועית בעת שימוש בפתרונות לוח מוכן.

גדלי פתח מותאמים בתוך מימדים חיצוניים סטנדרטיים מספקים גמישות לפורמטים שונים של תמונות ולסגנונות הצגה יצירתיים. ספקים רבים של לוח מוכן מציעים תצורות פתח שונות עבור אותו מימד חיצוני, כדי לעמוד בדרישות של צילומי פנורמה, פורמטים ריבועיים ותמונות מלבניות מסורתיות. גמישות זו הופכת את הלוח המוכן לאפשרות משכנעת למגוון פרויקטים של תצליב.

סטנדרטים לאיכות וمواصفות חומרים

יתרונות הרכב חסר חומצה

קרטון חיתוך מדויק חסר חומציות מייצג את הסטנדרט הזהב ליישומי תצוגה ארכיונית, ומציע הרכב חסר pH שמונע נדידת כימיקלים ופירוק היצירה. דרישה זו הופכת להיות חשובה במיוחד בעת תצוגת צילומים יקרים, יצירות מקור או מסמכים המיועדים לתצוגה לטווח ארוך. ההשקעה בקרטון חיתוך מדויק חסר חומציות איכותי משתלמת דרך שימור מושך של היצירה ושימור המראה החזותי שלה.

בנייה חסרת ליגנין מגבירה עוד יותר את התכונות הארכיוניות של אפשרויות קרטון חיתוך מדויק מתקדמות. דרישה זו מבטיחה שהקרטון לא יחליד או יהפוך שביר לאורך תקופות ארוכות, וימשיך לשמור על שלמותו המבנית והמראה החזותי שלו במשך עשורים. שומרי אוצרות מקצועיים ממליצים באופן עקבי על קרטון חיתוך מדויק חסר ליגנין ליישומי תצוגה באיכות מוזיאון ושימור יצירות יקרות.

עקביות צבע ועמידות לעיור

היציבות הצבעונית של לוחות חתיכה מוכנים תלויה באיכות הפיגמנטים ובתהליכי הייצור המשמשים בתהליך הייצור. מוצרים מובילים של לוחות חתיכה מוכנים שומרים על צביעה עקביות תחת מגוון מצבורי תאורה ועמידים בפני איבוד צבע upon חשיפה לאור סביבתי לאורך תקופה ממושכת. מאפיין זה חשוב במיוחד ליישומי תצוגה מסחריים ולתפישות דירות בסביבות בהירות.

דרגות עמידות לאור מספקות מדידה אובייקטיבית של עמידות בפני איבוד צבע, כאשר דירוגים גבוהים יותר מצביעים על ביצועים טובים יותר תחת תנאי תאורה מאתגרים. בעת בחירת לוחות חתיכה מוכנים ליישומים בעלי ראות גבוהה או ליצירות אמנות יקרות, עדיפויות למוצרים עם אישורי עמידות לאור מתועדים מבטיחה שביעות רצון ארוכת טווח ותוצאות מקצועיות השומרות על המראה המיועד שלהן.

טכנiques של אפליקציה מקצועית

טיפול והתקנה מתאימים

התקנת לוח חיתוך מדויק מצריכה תשומת לב לנקיון ולטכניקות טיפול מתאימות שנועדו למנוע נזק ומבטיחות תוצאות מקצועיות. ידיים נקיות ומשטחי עבודה נקיים מפחיתים את הסיכון להעברת שומנים, אבק או רטיבות אל פני השטח של לוח החיתוך, מה שיכול ליצור כתמים קבועים או שינוי צבע. מסגרים מקצועיים מדגישים את חשיבותם של סביבות מבוקרות עבור לוח מסגרת חתוך מראש טיפול והרכבה.

טכניקות מיקום משפיעות הן על התוצאה האסתטית והן על השלמות המבנית של היצירה המסגרת הסופית. חישובי מרכז מבטיחים שיווי משקל חזותי, בעוד מיון נכון מונע התקנות עקומות שמחלישות את ההצגה הכוללת. מוצרים מקצועיים של לוח חיתוך מדויק כוללים לעיתים קרובות הדרכה מובנית עדינה שעזר בהצבה מדויקת במהלך ההתקנה.

שילוב עיצוב יצירתי

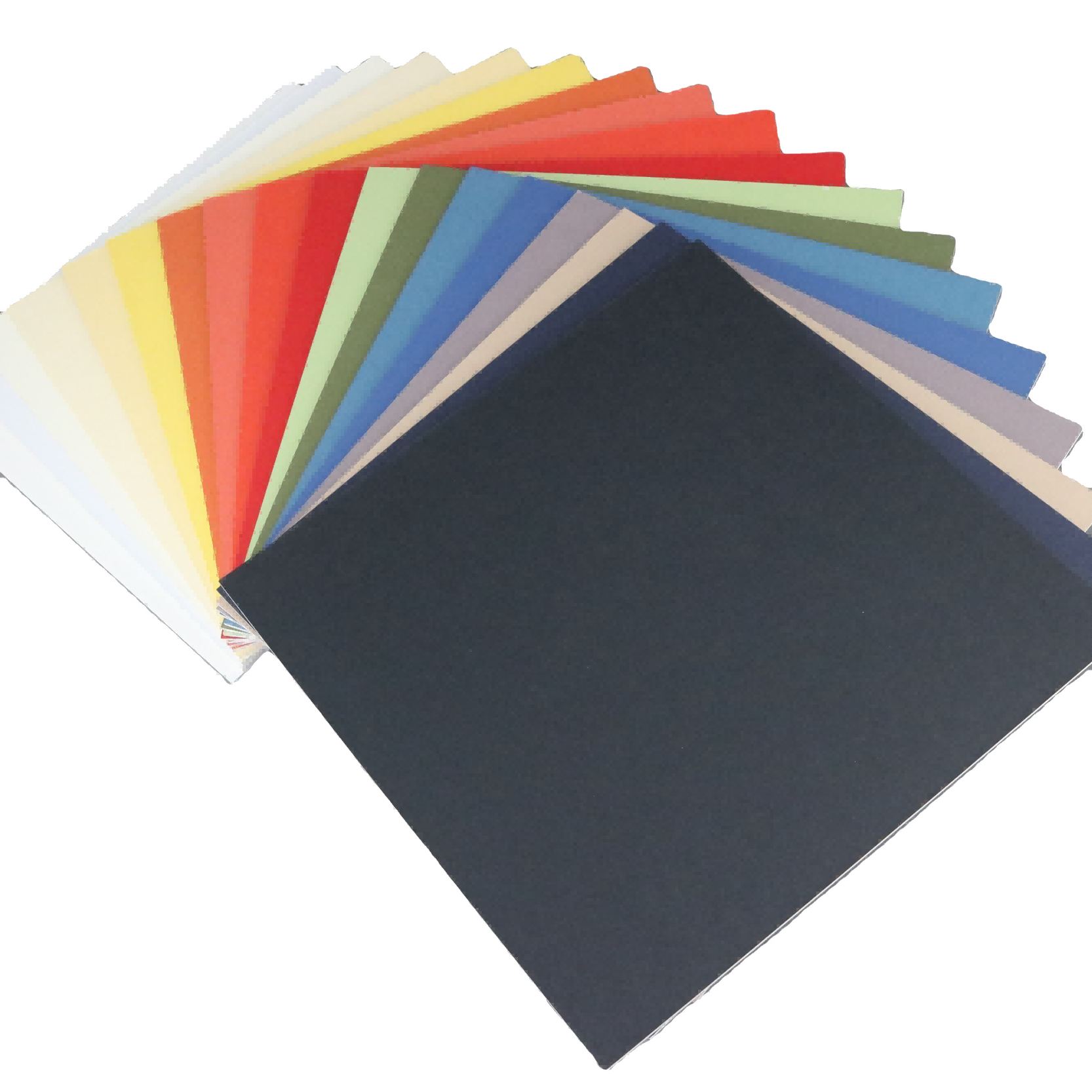

התאמת צבעים בין בחירות של לוחות מתניע מוכנות לגודל לבין היצירה דורשת הבנה של עקרונות תיאוריית הצבעים ושקול לסביבת התצוגה המיועדת. גוונים ניטרליים מספקים אפשרויות רב-שימושיות שמתאימות לסגנונות יצירה שונים, בעוד שצבעים בולטים יכולים ליצור אפקטים דרמטיים שמגבירים ערכיות עיצוביות מסוימות. המפתח הוא בבחר בצבעי לוח מתניע מוכנים שמעודדים את היצירה הראשית ולא מתחרים בה.

טכניקות תрамית מרובות המשתמשות בלוח מתניע מוכן יוצרות אפקטים שכבותיים sofisticated שמוסיפים עומק חזותי ומסיימים מקצועיים. שילובי תרמית כפולה או משולשת מאפשרים משחק צבעים יצירתי ויכולים ליהנות מיצירות בעלות פלטת צבעים מאתגרת. טכניקות מתקדמות אלו מדגימות את הגיוון העומד לרשותכם בעת עבודה עם מערכות לוח מתניע מוכן באיכות גבוהה.

יעילות עלות וניתוח ערך

השוואת אפשרויות רכישה

אסטרטגיות רכישה בכמות גדולה יכולות לצמצם משמעותית את עלות היחידה של לוחות מתאר חתוכים מראש, תוך הבטחת מלאי עקבי לפרויקטים מתמשכים של מסגרות. רבים מהספקים מציעים הנחות כמות שגורמות לרכישות בכמות גדולה להיות מפתות הן לבעלי מקצוע בתחום המסגרות והן לחובבים ברצינות. עם זאת, יש לקחת בחשבון שיקולים של אחסון ועקביות צבע לאורך דרכי ייצור שונות לצורך הערכת זהירה בעת תכנון רכישות בכמות גדולה של לוחות מתאר חתוכים מראש.

היחס בין איכות למחיר בשוק הלוחות המתאר החתוכים מראש משקף הבדלים בחומרים, במדויקות הייצור ובسمועת המותג. אם כי אפשרויות 저ות מחיר עשויות להיראות מפתות ליישומים לא פורמליים, לעתים קרובות העלויות ארוכות הטווח של החזרה ולפיכך נזק אפשרי ליצירות אומנות מוצדקות את ההשקעה במוצרים איכותיים יותר של לוחות מתאר חתוכים מראש. בעלי מקצוע בתחום המסגרות מדווחים באופן עקבי על שביעות רצון גבוהה יותר של לקוחות כאשר הם משתמשים באפשרויות מתקדמות של לוחות מתאר חתוכים מראש.

חיסכון בזמן ובעבודה

חישובי עלות עבודה מראים יתרונות משמעותיים של לוחות חיתוך מוקדמים לעומת פעולות חיתוך מסורתיות, במיוחד עבור גדלים סטנדרטיים ויישומים בנפח גבוה. הסרת שלבי המדידה, סימון והחתכה מקצרת את זמני השלמת הפרויקט, ובמקביל מפחיתה את הסיכון לשגיאות שדורשות החלפת חומר. הרווחים ביעילות מתורגמים ישירות להגדלת הרווחיות של פעולות מסחריות ולשיפור החוויה של חובבי עשיית מסגרות.

השוואות השקעה בציוד מראות כי פתרונות של לוחות חיתוך מוקדמים יכולים לדחות או אפילו להימנע מהצורך בציוד חיתוך יקר ובהוצאות התפעול והתחזוקה הקשורות אליו. שיקול זה חשוב במיוחד לעסקים חדשים בתחום עשיית המסגרות או למשתמשים מזדמנים שלא יכולים להצדיק השקעות גדולות בציוד. לוחות חיתוך מוקדמים באיכות גבוהה מספקים תוצאות מקצועיות ללא צורך בכלים מיוחדים או הדרכה מתקדמת.

אחסון וניהול מלאי

תנאי אחסנה אופטימליים

טכניקות אחסון מתאימות שומרות על איכות לוחות חיתוך מוכנים ומחזקות את תקופת השימוש האפקטיבית, ומحمיות את ההשקעה בחומרים איכותיים תוך הבטחת תוצאות עקביות בין פרויקטים מרובים. סביבות עם בקרת אקלים מונעות עיוות ושינויים בממדים שעלולים להשפיע על התאמת החיתוך והמראה. אחסון אופקי מפחית את המתח על שולי הלוחות החתוכים מראש ומשמר פרופיל שטוח החיוני להתקנות מקצועיות.

אמצעי הגנה מפני אבק מונעים זיהום של המשטח שעלול לעבור ליצירת האמנות או ליצור פגמים גלויים בפרויקטי תצורה סופיים. מערכות אחסון מקצועיות כוללות לעתים קרובות כיסים מגינים או מעטפות שמגן על משטחי לוחות חיתוך מוכנים תוך מתן גישה קלה במהלך הרכבת הפרויקט. אמצעי ההגנה הללו חשובים במיוחד בסביבותワーク숍 בעיירות בהן חלקיקים באוויר עלולים לפגוע באיכות החומר.

סיבוב מלאי ותכנון

תכנון מלאי אסטרטגי מבטיח זמינות של לוחות חיתוך מוכנים לפרויקטים צפויים, תוך מינימום של עלויות אחסון וצורך בשטח איחסון. הבנת דפוסי ביקוש עונתיים והעדפות לקוחות עוזרת לאופטימיזציה של הרכב המלאי ומצמצמת את הסיכון הצטברות מלאי מיושן. ניהול מלאי מוצלח של לוחות חיתוך מוכנים מאוזן בין מגוון למגבלות איחסון מעשיות.

עקרון הסיבוב ראשון פנימה ראשון החוצה שומר על תקיפות החומר ומונע ירידה באיכות עקב גיל של מלאי לוחות חיתוך מוכנים. אף שמוצרי חומצה חסרי איכות שומרים על יציבות לתקופות ארוכות, סיבוב תקין מבטיח שכל החומרים יפעלו בהתאם לדרישות המוגדרות. עיקרון זה מקבל חשיבות מיוחדת לעסקים עם קצב סיבוב מלאי איטי יותר.

פתרון בעיות נפוצות

בעיות דיוק ממדי

הבדלי גודל בלוחות מתאם חתוכים מראש עלולים להיגרם מסובלנות ייצור, תנאים סביבתיים או שגיאות מדידה בעת הזמנה. הבנת טווחי סובלנות מתקבלים עוזרת להבחין בין וריאציות רגילות לבין מוצרים פגומים הדורשים החלפה. ספקים איכותיים מספקים مواصفות ברורות בנוגע לדיוק ממדי ולמדיניות החזרה של מוצרים העולים על סובלנות מתקבלת.

גורמים סביבתיים כגון רטיבות ושינויי טמפרטורה יכולים להשפיע על מידות הלוחות החתוכים מראש, במיוחד במוצרים המכילים סיבים טבעיים או חומרים היגרוסקופיים. תקופות הסתגלות מאפשרות לחומרים להתייצב בסביבת ההתקנה, ובכך מפחיתות את הסיכון לשינויים ממדיים לאחר ההתקנה שעלולים להשפיע על התאמת המסגרת או על מיקום היצירה. צונחי קירוב מקצועיים שומרים לעתים קרובות על סביבות עבודה מבוקרות כדי למזער משתנים אלו.

אי-שקיפות משטח

פגמים במשטח של לוחות חתירה מוכנים עשוים לכלול שריטות, קימורים או הבדלי צבע העלולים להשפיע על המראה הסופי של חתיכות מסגרות. הליכי בקרת איכות בתהליך הייצור וההפצה מפחיתים את הבעיות הללו, אך פרוטוקולי בדיקה עוזרים לזהות בעיות לפני תחילת ההתקנה. הבנת מדיניות החזרה של הספקים וסטנדרטי האיכות מבטיחה אפשרות טיפול מתאימה במקרה של התגלות מוצרים פגומים.

שיטות ניקוי למשטחי לוחות חיתוך מוכנים דורשות גישה עדינה שמסירה שאריות זרות מבלי לפגוע בחומר או לשנות את מראהו. מוצרים ושיטות ניקוי מתאימים משתנים בהתאם לרקמת המשטח ולהרכבו, כאשר חלק מהחומרים מצריכים הליכי ניקוי מיוחדים כדי לשמור על מראהם וביצועיהם כמתוכננים.

שאלות נפוצות

מה גורם ללוחות חיתוך מוכנים חסרי חומצה להיות טובים יותר מאפשרויות רגילות

קרטון ח framing חסין חומצות מונע נדידת חומרים כימיים שتسبب בהתרוקנות ובלבול של יצירות אמנות לאורך זמן. הרכב ניטרלי ה-pH מבטיח יציבות ארוכת טווח ועקביות צבע, מה שmakes אותו חיוני לצלומים ויצירות אמנות יקרות. בעוד שקרטון framing רגיל עלול להיות זול יותר בתחילה, האפשרויות החסינות לחומצות מספקות מאפייני שימור מוכרים שמהווים הצדקה להשקעה בפרויקטי framing חשובים.

איך אני קובע את גודל הקרטון החיתוך המוכן הנכון ליצירת האמנות שלי

מודדים תחילה את ממדי יצירת האמנות, ולאחר מכן בוחרים בקרטון חיתוך מוכן שגודלי הפתח שלו מספקים שוליים מתאימים סביב התמונה. פרופורציות סטנדרטיות מאפשרות בדרך כלל שוליים של 2-3 אינץ' מכל צד, אם כי העדפות אומנותיות עשויות להשתנות. יש לקחת בחשבון הן את ממדי המסגרת החיצוניים והן את ההשפעה החזותית הרצויה בבחירת גודלי קרטון חיתוך מוכן לפרויקטים מסוימים.

האם ניתן להתאים אישית קרטון חיתוך מוכן לגודלי יצירות אמנות לא סטנדרטיים

רבים מספקים מציעים שירותי חיתוך מותאמים ללוחות מתנה לפי מידה מוכנים כאשר גודל סטנדרטי אינו מתאים למימדי יצירה מסוימים. עם זאת, מידות מותאמות באמת עלולות לבטל את הנוחות והיתרון הכלכלי של אפשרויות חיתוך מוכן. שקול אם מידות סטנדרטיות עם מיקום מתוקן עשויות להשיג תוצאות דומות תוך שמירה על היתרונות של מערכות לוחות מתנה לפי מידה מוכנות.

אילו תנאי אחסון שומרים על איכות לוחות מתנה לפי מידה מוכנים למשך זמן ארוך ביותר

אחסן את לוחות המתנה לפי מידה המוכנים אופקית בסביבות נקיות ויבשות עם טמפרטורות ורמות רטיבות יציבות. הסר מהאור השמש הישיר ושמר על המשטחים מפני אבק ונזק פיזי. טכניקות אחסון מתאימות יכולות להאריך בצורה משמעותית את חיי השימוש, ולשמור הן על איכות החומר והן על ערך ההשקעה עבור פרוייקטים עתידיים של תצלומים הדורשים פתרונות לוחות מתנה לפי מידה מוכנים באיכות מקצועית.