Raminxhimi profesional kërkon precizion, materiale të cilësisë dhe një kuptim se si pjesët e ndryshme punojnë së bashku për të mbrojtur dhe theksuar veprat e artit. Në mes të elementeve më të rëndësishme në çdo projekt raminxhimi është tabaka e papërputhur, e cila shërben si pengesë mbrojtëse dhe si një theks estetik për fotografi, printime dhe vepra arti. Zgjedhja e një tabake të përshtatshme të papërputhur mund të ketë një ndikim të madh në jetëgjatësinë e veprave të raminxhuara, duke kontribuar gjithashtu në atraktivitetin vizual dhe paraqitjen profesionale të tyre.

Industria e kornizimit ka evoluar në mënyrë të konsiderueshme gjatë viteve të fundit, me prodhues që zhvillojnë materiale të avancuara të cilat ofrojnë mbrojtje superiore kundër faktorëve mjedisore, duke ruajtur njëkohësisht efikasitetin në kosto për ngjitësit profesionalë dhe entuziastët DIY. Njohja e karakteristikave të opsioneve të ndryshme të pllakave të pasqyrës së papërpunuar lejon marrjen e vendimeve të informuara që garantojnë rezultate optimale për çdo projekt kornizimi, pavarësisht nga madhësia apo kompleksiteti.

Teknikat moderne të ruajtjes theksojnë rëndësinë e materialeve pa acid në parandalimin e degradimit të veprave të vlerëshme artistike dhe fotografive. Pllaka e mirë e papërpunuar e matit shërben për funksione të shumta përtej thjesht përmirësimit estetik, duke përfshirë krijuar hapësirë ajrore të nevojshme midis xhamit dhe veprës, parandalimin e kontaktit direkt që mund të shkaktojë dëmtime, dhe sigurimin e një sipërfaqe të qëndrueshme montimi për teknika të ndryshme ekspozimi.

Kuptimi i Përbërjes dhe Materialeve të Pllakës së Matit

Pllaka e Matit Pa Acid kundrejt Përbërjes Standarde

Ndryshimi themelor midis kartonit të papaguar konservues dhe atij standart të papaguar qëndron në përbërjen kimike dhe proceset e prodhimit. Kartoni i papaguar pa acid prodhohet duke përdorur pulpag të purifikuar druri ose fibra pambuku që janë trajtuar për të eliminuar ligninën dhe komponimet e tjera acide që mund të shkaktojnë ngjyrim të verdhë dhe degradim me kalimin e kohës. Ky proces trajtimi siguron që kartoni i matricës të ruaj strukturën e tij të pandalshme dhe stabilitetin e ngjyrës për dhjetëra vjet, gjë që e bën të domosdoshëm për ruajtjen e veprave të vlefshme të artit dhe fotografive.

Kartoni standard i matricës, megjithëse më ekonomik, përmban ligninë dhe komponime organike të tjera që shkatërrohen gradualisht, duke liruar acide që mund të migrojnë tek materialët pranë tyre. Rahunjtë profesionalë zakonisht rekomandojnë karton matrice pa acid për çdo veprë që synon ekspozim afatgjatë ose sende me vlerë sentimentale apo monetare. Investimi në materiale cilësore sjell fitime në rezultatet e ruajtjes dhe kënaqësinë e klientit.

Proceset e prodhimit për kartonin premium të paprezuar shpesh përfshijnë agjentë shtesë neutralizues që asnjanë acidet nga mjedisi dhe ofrojnë mbrojtje të vazhdueshme. Këta kartonë nënshtrohen testimeve të ashpra për të siguruar se plotësojnë standardet e konservimit të vendosura nga muzeut dhe institucionet arkivore në mbarë botën.

Materialet e Bërthamës dhe Karakteristikat e Performancës

Materiali i bërthamës së kartonit të paprezuar ndikon në mënyrë të konsiderueshme në performancën, qëndrueshmërinë dhe përshtatshmërinë e tij për aplikime të ndryshme. Bërthamat nga pulpa druri solide ofrojnë stabilitet të shkëlqyeshëm dhe karakteristika prerjeje, gjë që i bën të popullarizuara tek raminat profesionalë që kërkojnë skeda të pjerrëta të pasterta dhe precize. Këto tabla zakonisht kanë dendësi uniforme në tërë trashësinë e tyre, duke garantuar rezultate të qëndrueshme kur priten forma komplekse ose hapje të shumta.

Bërthamat nga fibra pambuku përfaqësojnë opsionin premium në plakë mat e pa ndjeshur konstruksion, ofron gjatësi më të madhe të jetës dhe stabilitet kimik tërheqës. Tavolinat me bazë pambuku rezistojnë më mirë ndaj deformimeve dhe ndryshimeve dimensionale sesa alternativat nga pulpa e drurit, çfarë i bën ideale për format e mëdhenj ose kushte të vështira mjedisore. Ekuilibri natyral i pH-së të fibrave të pambukut ofron mbrojtje të brendshme kundër migrimit të acidit.

Tavolinat me qendër djell kombinojnë një strukturë të lehtë me veti izoluese të shkëlqyera, gjë që i bën të përshtatshme për aplikime ku zvogëlimi i peshës është i rëndësishëm. Megjithatë, këto tavolina kërkojnë kujdes të veçantë gjatë prerjes për të parandaluar shkëputjen ose ekspozimin e bërthamës, gjë që mund të komprometojë cilësitë e tyre mbrojtëse.

Zgjedhja e Ngjyrave dhe Konsideratat Estetike

Tona Neutrale për Aplikime të Larmishme

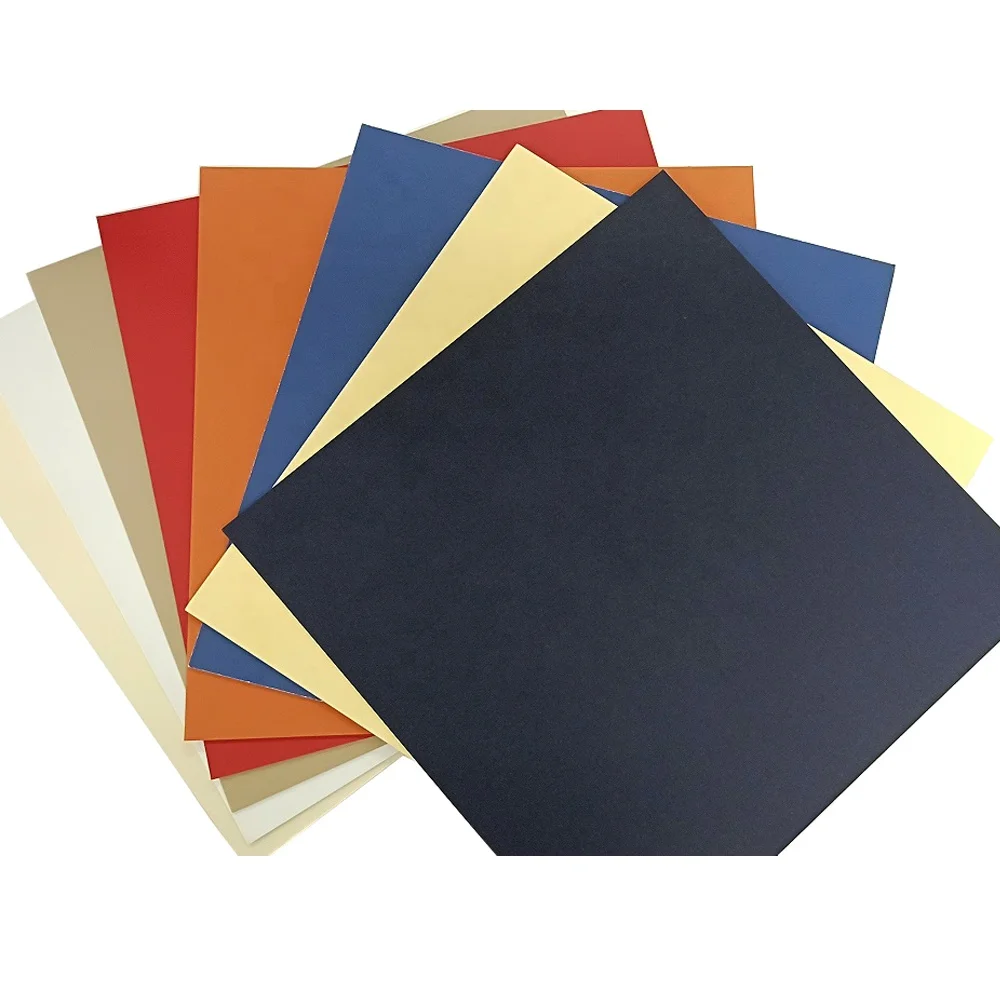

Zgjedhja e ngjyrave të përshtatshme për tabaken e papërpunuar kërkon njohuri se si ndryshojnë huet e ndryshme me veprën e artit dhe ndikojnë në perceptimin e shikuesit. Ngjyrat e ashpër, si bardha, krem dhe gri e lehtë ofrojnë opsione të përshtatshme që përshtaten me shumicën e veprave të artit pa u përplasur për vëmendje apo duke krijuar reflektime të padëshiruara të ngjyrës. Këto ngjyra kanë vërtetuar efikasitetin e tyre në aplikime të ndryshme, nga riprodhimi i artit të shtrenjtë deri te ekspozimi i fotografisë komerciale.

Tabakja e papërpunuar e bardhë ofron kontrastin dhe ndriçimin maksimal, duke e bërë veçanërisht efektive për fotografinë në ngjyrë të zezë dhe të bardhë ose për veprat e artit me variacione tonale të hollësishme. Megjithatë, bardha e theksuar nganjëherë mund të duket e ashpër pranë veprave të artit me ngjyra të ngrohta, duke kërkuar kujdes të veçantë për qëllimet e përgjithshme të prezantimit. Alternativat e krem dhe të bardhosur ofrojnë zgjidhje më të buta që ruajnë ndriçimin, por ofrojnë ndërveprime më të favorshme me paletat e ngjyrave të ngrohta.

Tonet e gri në kartonin e papërpunuar krijojnë prezantime sofistikate që funksionojnë veçanërisht mirë me veprat e artit dhe fotografinë bashkëkohore. Grija e lehtë ofron kontrast të butë pa mbizotëruar mbi imazhet e delikta, ndërsa griet e mesme mund të shtojnë thellësi dhe pasuri në prezantime. Kyça qëndron në zgjedhjen e toneve gri që përmirësojnë veprën kryesore, pa u garuar me të.

Ngjyra të forta dhe aplikime speciale

Kartoni i papërpunuar me ngjyra të forta mund të krijojë prezantime dramatike kur përdoret në mënyrë të përshtatshme, megjithëse këto aplikime kërkojnë konsideratë të kujdesshme të teorisë së ngjyrave dhe parimeve të dizajnit. Kalamet e thella, burgundet e pasura dhe gjelbërt e pyllit mund të ofrojnë kontrast të thellë për lloje të caktuara veprash, veçanërisht kur ngjyra e kartonit përshtatet ose kontraston me qëllim me ngjyrat dominuese në veprë.

Opsionet e veçanta për tabelat e papërpunuara përfshijnë sipërfaqe me teksturë, përfundime metalike dhe variante të mbuluara me stof që shtojnë interes taktil në prezantimet. Këto materiale kërkojnë teknika dhe mjete të specializuara prerjeje për të arritur rezultate profesionale, gjë që i bën më të përshtatshme për ato që ngjajnë me përvojë ose për aplikime artistike specifike ku efekti vizual i theksuar e vlen kompleksitetin shtesë.

Tabela e zezë e papërpunuar krijon prezantime dramatike, me stil galerie, që funksionojnë shumë mirë me fotografi me kontrast të lartë dhe vepra të artit bashkëkohor. Megjithatë, ngjyra e zezë tregon më lehtë pluhurin dhe gjurmët e gishtave sesa ngjyrat më të drita, duke kërkuar kujdes shtesë gjatë manipulimit dhe mirëmbajtjes. Ndikimi psikologjik i rameve të zeza tendos të fokusohet thellësisht në veprën e artit, gjë që e bën të përshtatshme për veprat që përfitojnë nga një vëzhgim të tillë të përqendruar.

Madhësitë dhe Konsideratat Dimensionale

Madhësitë Standarde të Fletave dhe Kërkesat e Planifikimit

Njohja e dimensioneve standarde për tabelat e papërpunuara të materjalit lejon planifikim efikas projektimi dhe optimizim të kushteve. Shumica e furnitorëve ofrojnë fletë me madhësi të zakonshme si 20x32 inç, 32x40 inç dhe 40x60 inç, me këto dimensione që janë projektuar për të maksimizuar prodhimin gjatë prerjes së madhësive standarde të kornizave. Ata që bëjnë korniza profesionistë zakonisht kanë në stok disa madhësi për t'u përshtatur me kërkesat e ndryshme të projekteve, ndërkohë që minimizojnë humbjet dhe sfidat e depozitimit.

Planifikimi i skemave të prerjes para se të blihen tabelat e papërpunuara të materjalit ndihmon në optimizimin e përdorimit të materialit dhe në uljen e kushteve, veçanërisht për projekte të mëdha apo për punë serike. Mjete softuerike dhe stampa skemash mund të ndihmojnë në përcaktimin e madhësive më efikase të fletëve për kërkesat specifike të projektit, duke marrë parasysh gjerësinë e thikës, këndet e pjerrëta dhe marginet e sigurisë gjatë operacioneve të prerjes.

Opsionet e madhësisë të personalizuara janë të disponueshme nga shumë furnitorë, megjithëse këto zakonisht kanë çmime më të larta dhe kohë dorëzimi më të gjata. Fletët e paneza të tabelave mat kapshëm lejojnë prezantimin e pazbehur të veprave të mëdha të artit pa nyje ose bashkime të dukshme, por kërkojnë pajisje të specializuara për manipulim dhe prerje për të arritur rezultate profesionale.

Ndryshimet e Trashësisë dhe Ndikimi në Performancë

Zgjedhja e trashësisë së tabelave mat kapshëm të paprezura ndikon si në performancën funksionale ashtu edhe në prezantimin estetik. Tabelat standarde 4-pjese (rreth 1,6 mm të trasha) ofrojnë ngurtësi të mjaftueshme për shumicën e aplikacioneve, duke mbetur të lehta për t'u prerë me vegla standarde. Kjo trashësi ofron stabilitet të mirë dimensional dhe krijon thellësi të duhur hijete për shumicën e madhësive të veprave.

Opsionet e tavolinave të papërpjekura me gjashtë shtresa dhe tetë shtresa (rreth 2,4 mm dhe 3,2 mm përkatësisht) ofrojnë rigjiditet strukturor të theksuar dhe krijojnë vija hijesh më të mëdha që mund t'i shtojnë thellësi dramatike paraqitjeve. Këto tabla më të trasha funksionojnë veçanërisht mirë me vepra arti tre dimenzionale ose kur dëshirohen shumë shtresa mat për paraqitje komplekse. Megjithatë, trashësia e rritur kërkon vegla prerëse më të mprehta dhe teknikë më të kujdesshme për të arritur skaje të pjerrëta të pastërta.

Tavolinat speciale të holla, zakonisht me ndërtim 2-shtresësh, shërbejnë aplikacioneve specifike ku kërkohet minimizimi i trashësisë ose ku tabela e mat do të laminohet në materiale të tjera. Këto tabla kërkojnë trajtim të kujdesshëm për të parandaluar dëmtimin gjatë prerjes dhe instalimit, por ofrojnë mundësi unike paraqitjeje për projekte të specializuara.

Teknikat e Prerjes dhe Kërkesat për Veglat

Metodat Manuale të Prerjes dhe Praktikat Më të Mirë

Prerja e suksesshme e tabakës së papërshkruar kërkon mjete të përshtatshme, teknikë të duhur dhe njohuri të karakteristikave të materialit. Prerësit profesionalë të tabakave ofrojnë saktësinë dhe përshtatshmërinë e nevojshme për skaje të pjerrëta të pastër, ndërsa mjetet e prerjes me dorë janë të mjaftueshme për përdorim të rrallë ose prera të thjeshta drejtkëndore. Kyça i prerjes së suksesshme gjendet në ruajtjen e thikave të mprehta dhe shtypjes së qëndrueshme gjatë secilës prerje.

Teknikat e matjes dhe shënjimit kanë një ndikim të madh në rezultatin përfundimtar kur punohet me tabakë të papërshkruar. Raminuesit profesional zakonisht përdorin vizore dhe mjete matëse të specializuara të dizajnuara për prerjen e tabakave, duke siguruar saktësi dhe riprodhimtari të njëjtës masë nëpër copa të shumta. Teknikat e duhura të shënjimit minimizojnë vijat e dukshme të udhëzimit, duke ofruar njëkohësisht pika referimi të nevojshme për prerje të sakta.

Prerja e pjerrësht kërkon kënde të veçantë të thikës dhe teknika prerjeje për të arritur rezultate profesionale. Shumica e aplikimeve me karton mat që nuk janë të prerë përfitojnë nga skajet e pjerrësht me 45 gradë që krijojnë vija hijesh të pasterta dhe pamje profesionale. Ruajtja e një këndi konstant të thikës gjatë procesit të prerjes kërkon ushtrim dhe vëmendje ndaj teknikës, veçanërisht kur punohet me shtresa më të trasha ose materiale sfiduese.

Makina Elektrike dhe Konsiderata Prodhimi

Prerësit elektrikë mat dhe sistemet kompjuterizuar prerjesh ofrojnë përfitime për prodhimin me vëllim të lartë ose kërkesa të komplikuara të prerjes. Këto mjete ofrojnë rezultate të qëndrueshme, zvogëlojnë lodhjen e operatorit dhe lejojnë riprodhimin e formave të komplikuara dhe hapjeve të shumta me saktësi të lartë. Megjithatë, ato kërkojnë investime të konsiderueshme dhe trajnim për t'u përdorur në mënyrë efektive.

Konsideratat e sigurisë bëhen veçanërisht të rëndësishme kur punohet me pajisje prerëse elektrike dhe karton pa pritur. Ventilimi i duhur ndihmon në menaxhimin e pluhurit që gjenerohet gjatë operacioneve të prerjes, ndërsa pajisjet e sigurisë adekuate e mbrojnë operatorët nga lëndimet nga thikat. Mirëmbajtja e rregullt e pajisjeve të prerjes siguron performancë optimale dhe zgjat jetëgjatësinë e thikave.

Planifikimi i prodhimit për sasi të mëdha të prerjes së kartonit të papritur përfiton nga përpunimi i partive dhe procedurat standarde. Grupimi i prerjeve të ngjashme, paragjatësia e shumë copave dhe organizimi i rrjedhës së punës mund të përmirësojnë në mënyrë të konsiderueshme efikasitetin, ruajtjen e standardit të cilësisë. Raminuesit profesionalë zakonisht zhvillojnë protokolle specifike për lloje të ndryshme operacionesh prerjesh për të maksimizuar produktivitetin.

Vlerësimi i Cilësisë dhe Kriteret e Zgjedhjes

Metodat e Inspektimit Vizual dhe Fizik

Vlerësimi i cilësisë së tavolinës së paprezur të materjecelës kërkon një kontroll sistematik si të karakteristikave të sipërfaqes ashtu edhe të vetive strukturore. Kontrolli i sipërfaqes duhet të identifikojë çdo ngjyrëzim, variacione në teksturë ose defekte prodhimi që mund të ndikojnë në paraqitjen përfundimtare. Një tavolinë e mirë e paprezur e materjecelës ruajnë ngjyrën dhe tekaturën konstante në tërë fletën, pa modele të dukshme gruri apo të metash në sipërfaqe.

Vlerësimi i cilësisë së skajit përfshin analizimin e mostrave të prepra për të vlerësuar sa pastaj materiali copëtohet dhe nëse ngjyra e bërthamës përputhet me ngjyrën e sipërfaqes. Materjecela e lartë cilësie duhet të preset pastaj pa shkëputje apo zhduke, duke prodhuar skaje të pjerrëta të rrjedhshme që përmirësojnë pamjen profesionale të kuadreve të përfunduara. Përputhja e ngjyrës së bërthamës parandalon vijat e dukshme kontrasti që mund të zvogëlojnë cilësinë e paraqitjes.

Testimi i fleksibilitetit ndihmon në përcaktimin e integritetit strukturor të tabakës së papërpunuar pa shkaktuar dëmtim. Tabakat e cilësisë duhet të tregojnë ngurtësi të përshtatshme për trashësinë e tyre, ndërkohë që rezistojnë çarjeve ose thyerjes nën shtresën normale të përdorimit. Duhet shmangur tabakat që tregojnë shenja të thyeshmërisë ose shkëputje shtresash, pasi këto karakteristika tregojnë probleme në prodhim ose kushte të papërshtatshme ruajtjeje.

Vlerësimi i Furnitorëve dhe Strategjitë e Furnizimit

Zgjedhja e furnitorëve të besueshëm për tabakën e papërpunuar përfshin vlerësimin e përshtatshmërisë së produktit, besueshmërisë në dorëzim dhe aftësive të mbështetjes teknike. Furnitorët e vendosur zakonisht ruajnë procedura kontrolli cilësie që garantojnë karakteristika të qëndrueshme të produktit nëpër seritë e ndryshme prodhimi, duke ulur ndryshueshmërinë në performancën e prerjes dhe pamjen vizuale.

Dokumentimi dhe certifikimi bëhen gjithnjë e më të rëndësishëm kur punohet me karton mat i paprezuar të klasës për ruajtje. Furnitorët e respektueshëm ofrojnë specifikime të hollësishme, përfshirë nivelet e pH-së, rezultatet e testeve të vjetrimit dhe zbatimin e standardeve industriale të rëndësishme. Ky dokument është i domosdoshëm për qëllime sigurimi dhe besimi të klientit kur kornizohet vepra e artit me vlerë.

Strategjitë e menaxhimit të inventarit ndihmojnë në optimizimin e kostove, duke garantuar disponueshmërinë e produkteve për projekte urgjente. Shumë kornizues profesionalë themelojnë marrëdhënie të vazhdueshme me furnitorë që ofrojnë çmime të favorshme për porosi të rregullta, duke ruajtur njëkohësisht hyrjen në produktet specializuese për aplikime unike. Blerja në sasi të mëdha mund të ofrojë avantazhe të konsiderueshme në çmim, megjithëse kërkohet një hapësirë e mjaftueshme ruajtjeje dhe sisteme të gjurmimit të inventarit.

Praktikat më të mira për ruajtje dhe manipulim

Kërkesat e Kontrollit të Mjedisit

Ruajtja e duhur e tabakës së paprezuar kërkon kushte të kontrolluara mjedisore që parandalojnë deformimin, zhivijimin dhe forma të tjera dëmtimi. Stabiliteti i temperaturës është më i rëndësishëm se intervali specifik i temperaturës, me ndryshime të ngadalta të preferuara në vend të fluktuacioneve të shpejta që mund të shkaktojnë lëvizje dimensionale. Lagështia relative duhet të ruhet në mes të 45-55% për të parandaluar thithjen e lagështisë që çon në deformim ose instabilitet dimensional.

Menaxhimi i ekspozimit ndaj dritës e mbrojt tabakën e paprezuar nga zhivijimi dhe dëmtimi nga rrezet UV gjatë periudhës së ruajtjes. Drita e drejtpërdrejtë e diellit dhe drita artificiale me intensitet të lartë mund të shkaktojnë ndryshime ngjyrash dhe degradim të sipërfaqes, veçanërisht te tabakat me ngjyra. Zonat e ruajtjes duhet të ofrojnë mbrojtje nga ekspozimi ndaj dritës, duke ruajtur njëkohësisht dritshmeri të mjaftueshme për manipulim të sigurt dhe menaxhim të inventarit.

Qarkullimi i ajrit ndihmon në ruajtjen e kushteve të qëndrueshme rreth kartonave të paprezuar gjatë depozitimit, duke parandaluar grumbullimin e avujve kimikë që mund të shkaktojnë kontaminim. Ventilimi i mjaftueshëm gjithashtu ndihmon në kontrollin e nivелеve të lagështisë dhe parandalon zhvillimin e molit ose formimit të pluhurit në hapësirat e depozitimit. Megjithatë, duhet shmangur qarkullimi i tepërt i ajrit, pasi kjo mund të shkaktojë grumbullim pluhuri dhe lëkundje temperaturash.

Metodat e Përdorimit Fizik dhe Mbrojtjes

Teknikat e sigurt për përdorim parandalojnë dëmtimin e kartonit të paprezuar gjatë transportit dhe operacioneve të depozitimit. Depozitimi i shtrirë ofron mbrojtje optimale kundër deformimeve dhe dëmtimeve të skajeve, ndërsa sistemet vertikale të depozitimit lejojnë vendosjen e sasive më të mëdha në hapësira të kufizuara. Mbulesat mbrojtëse ose materiale të ndërmjetshme ndihmojnë në parandalimin e grykimeve në sipërfaqe dhe të kontaminimeve midis fletëve.

Procedurat e ngarkimit dhe shkarkimit duhet të minimizojnë tensionin mbi pllakat e pashkreta, veçanërisht për formatet më të mëdha që bëhen të papunueshme gjatë manipulimit. Ngarkimi me ekip për pllaka të mëdha parandalon lakimin dhe zvogëlon rrezikun e aksidenteve që mund të dëmtojnë si materialet ashtu edhe personelin. Teknikat e duhura të ngjitjes dhe organizimi i mjaftueshëm i hapësirës së punës kontribuojnë në operacione të sigurta dhe efikase.

Sistemet e gjurmimit të inventarit ndihmojnë në ruajtjen e cilësisë së produktit duke optimizuar kohët e përdorimit. Rrotullimi i parë brenda, i pari jashtë parandalon periudha të gjata ruajtjeje që mund të komprometojnë cilësinë e materialit, ndërsa gjurmimi i hollësishëm lejon identifikimin e problemeve të cilësisë para se të ndikojnë në projekte të klientëve. Sistemet dixhitale të inventarit mund të integrohen me software-ë për optimizim prerjesh për të përmirësuar efikasitetin e shfrytëzimit të materialeve.

FAQ

Cili është ndryshimi midis pllakave matë të paacidifikuara dhe atyre të rregullta të paprekura

Tavolina e papastër reziste ndaj acidit prodhohet duke përdorur materiale të pastra të cilat janë trajtuar për të hequr ligninën dhe komponime të tjera acide që shkaktojnë ngjyrimin në të verdhë dhe dëmtimin me kalimin e kohës. Tavolinat e zakonshme përmbajnë këto komponime, të cilat shkatërrohen gradualisht dhe mund të dëmtojnë veprat e artit fqinje përmes migrimit të acidit. Për veprat e vlefshme të artit ose aplikimet e ekspozimit afatgjata, opsionet rezistente ndaj acidit ofrojnë mbrojtje esenciale dhe ruajnë pamjen dhe integritetin strukturor për dhjetëra vite, ndërsa tavolinat e rregullta mund të tregojnë vjetërim të dukshëm brenda vetëm disa viteve.

Si mund ta caktoj madhësinë e duhur të tavolinës së papastër për projektin tim

Për të përcaktuar madhësinë e duhur të tabelës së paprezuar, matni përmasat e veprës suaj artistike dhe shtoni gjerësinë e dëshiruar të kornizës në të gjitha anët, si dhe një kufi shtesë për montimin dhe operacionet e prerjes. Shumica e projekteve kërkojnë të paktën 2-3 inç kornizë në secilën anë, megjithëse preferencat estetike mund të kërkojnë korniza më të gjera ose më të ngushta. Kini parasysh madhësinë përfundimtare të kornizës dhe sigurohuni që fleta juaj e tabelës së paprezuar është mjaftueshmërisht e madhe për të përfshirë tërësisht matracin me material të mjaftueshëm për manipulim të sigurt gjatë prerjes. Planifikimi i prerjeve tuaja në letër më parë ndihmon në optimizimin e përdorimit të materialit dhe siguron që të blini sasi të mjaftueshme.

A mund ta pres tabelën e paprezuar pa përdorur mjete specializuese

Ndërkohë që veglat e specializuara për prerjen e tapetave prodhojnë rezultatet më të mira, ju mund të prisni tapetin e paprisur duke përdorur një thikë të mprehtë dhe një cep të drejtë për forma të thjeshta drejtkëndëshe. Megjithatë, arritja e cepve të pjerrët të pastër kërkon ose një prusës dorash dore ose pajisje profesionale për prerje. Për projekte të rralla, një prusës i mirë dorash ofron rezultate të pranueshme, por puna profesionale ose me vëllim të lartë përfiton në mënyrë të konsiderueshme nga pajisjet e dedikuara për prerjen e tapetave. Pavarësisht nga veglat e përdorura, mbajtja e thikave të mprehta është e thelbësishme për prerje të pastër dhe parandalimin e copëzimeve apo cepve të papunuar.

Si duhet të ruaj tapetin e paprisur për të ruajtur cilësinë

Ruani panelin e paprezuar në një ambient të pastër, të thatë me temperaturë të qëndrueshme dhe nivеле laghjeje midis 45-55% lagështie relative. Mbajeni fletët sa më të sheshta të jetë e mundur, ose ruajini vertikalisht në mbulesa mbrojtëse për të parandaluar deformimin dhe dëmtimet e sipërfaqes. Mbroni nga eksponimi i drejtpërdrejtë ndaj dritës dhe grumbullimi pluhuri, dhe sigurojuni një ventilacion adekuat pa rrjedhë ajri të tepërt që mund të shkaktojnë lëkundje temperaturash. Përdorni rrotacionin e inventarit të parë-hyrës, i parë-dalës për të parandaluar periudha të gjata ruajtjeje, dhe kontrolloni rregullisht materialet e depozituara për shenja degradimi apo aktiviteti parazitësh që mund të komprometojnë cilësinë.

Përmbajtja

- Kuptimi i Përbërjes dhe Materialeve të Pllakës së Matit

- Zgjedhja e Ngjyrave dhe Konsideratat Estetike

- Madhësitë dhe Konsideratat Dimensionale

- Teknikat e Prerjes dhe Kërkesat për Veglat

- Vlerësimi i Cilësisë dhe Kriteret e Zgjedhjes

- Praktikat më të mira për ruajtje dhe manipulim

-

FAQ

- Cili është ndryshimi midis pllakave matë të paacidifikuara dhe atyre të rregullta të paprekura

- Si mund ta caktoj madhësinë e duhur të tavolinës së papastër për projektin tim

- A mund ta pres tabelën e paprezuar pa përdorur mjete specializuese

- Si duhet të ruaj tapetin e paprisur për të ruajtur cilësinë