Professional artists, framers, and art conservators understand that selecting the right materials is crucial for preserving artwork integrity over time. Among the most critical components in art preservation is uncut mat board, which serves as both a protective barrier and aesthetic enhancement for framed pieces. This specialized material provides essential spacing between artwork and glazing while offering archival protection against environmental factors that can damage precious artworks. Understanding the properties, applications, and selection criteria for uncut mat board enables professionals to make informed decisions that ensure long-term art preservation success.

Understanding Mat Board Composition and Properties

Core Materials and Manufacturing Process

The foundation of quality uncut mat board lies in its core composition, which typically consists of cotton fibers, wood pulp, or a combination of both materials. Premium grades utilize 100% cotton rag content, providing superior longevity and chemical stability compared to wood-based alternatives. The manufacturing process involves creating multiple layers that are compressed and bonded together, resulting in a uniform thickness that maintains structural integrity over time. Surface treatments are applied to achieve various textures and finishes, from smooth museum-grade surfaces to lightly textured options suitable for different artistic applications.

Modern production techniques ensure consistent density and thickness across large sheets of uncut mat board, eliminating variations that could compromise cutting accuracy or visual uniformity. Quality control measures include pH testing to verify acid-free properties and dimensional stability assessments that guarantee the material will not warp or deteriorate under normal storage conditions. The surface coating process involves applying specialized treatments that enhance durability while maintaining the material's archival characteristics, ensuring that the mat board contributes to rather than detracts from long-term artwork preservation.

Chemical Properties and Archival Standards

Archival quality uncut mat board must meet stringent chemical standards to ensure it does not contribute to artwork deterioration over time. The pH level should be neutral or slightly alkaline, typically ranging from 7.5 to 8.5, which prevents acid migration that could cause discoloration or chemical damage to adjacent materials. Lignin-free composition is essential, as this natural polymer found in wood can break down over time and release acidic compounds that compromise artwork integrity. Buffer agents are often incorporated into the manufacturing process to neutralize any acids that may develop through environmental exposure or aging.

Professional-grade uncut mat board undergoes rigorous testing according to industry standards, including the Photographic Activity Test (PAT) which evaluates potential interactions with photographic materials. These comprehensive assessments verify that the mat board will not cause fading, staining, or other forms of deterioration when in direct contact with artwork. Additionally, the material must demonstrate stability under various environmental conditions, including temperature fluctuations and humidity changes that are common in display and storage environments.

Selection Criteria for Different Applications

Museum and Conservation Requirements

Museum professionals and conservators require uncut mat board that meets the highest preservation standards for valuable and irreplaceable artworks. Conservation-grade materials must pass extensive aging tests that simulate decades of environmental exposure, proving their long-term stability and non-reactive properties. The selection process involves evaluating the board's ability to maintain structural integrity while providing consistent protection against dust, pollutants, and physical contact that could damage delicate surfaces. Color stability is another crucial factor, as museum-quality uncut mat board must resist fading or color shifts that could affect the visual presentation of displayed works.

Professional conservators often specify particular thickness requirements based on the artwork's dimensions and weight, ensuring adequate support without creating excessive bulk in framing assemblies. The board's cutting characteristics must allow for precise, clean edges that maintain their appearance over time without chipping or fraying. Surface texture considerations include evaluating how the mat board's finish complements different artistic media, from delicate watercolors to robust oil paintings, ensuring that the presentation enhances rather than competes with the artwork's visual impact.

Commercial Framing Applications

Commercial framing operations require uncut mat board that balances archival quality with practical considerations such as cost-effectiveness and processing efficiency. Professional framers must evaluate the material's compatibility with various cutting tools and techniques, ensuring consistent results across different production volumes. The board's dimensional stability becomes particularly important in commercial settings where materials may be stored for extended periods before use, requiring resistance to environmental variations that could affect cutting accuracy or finished appearance.

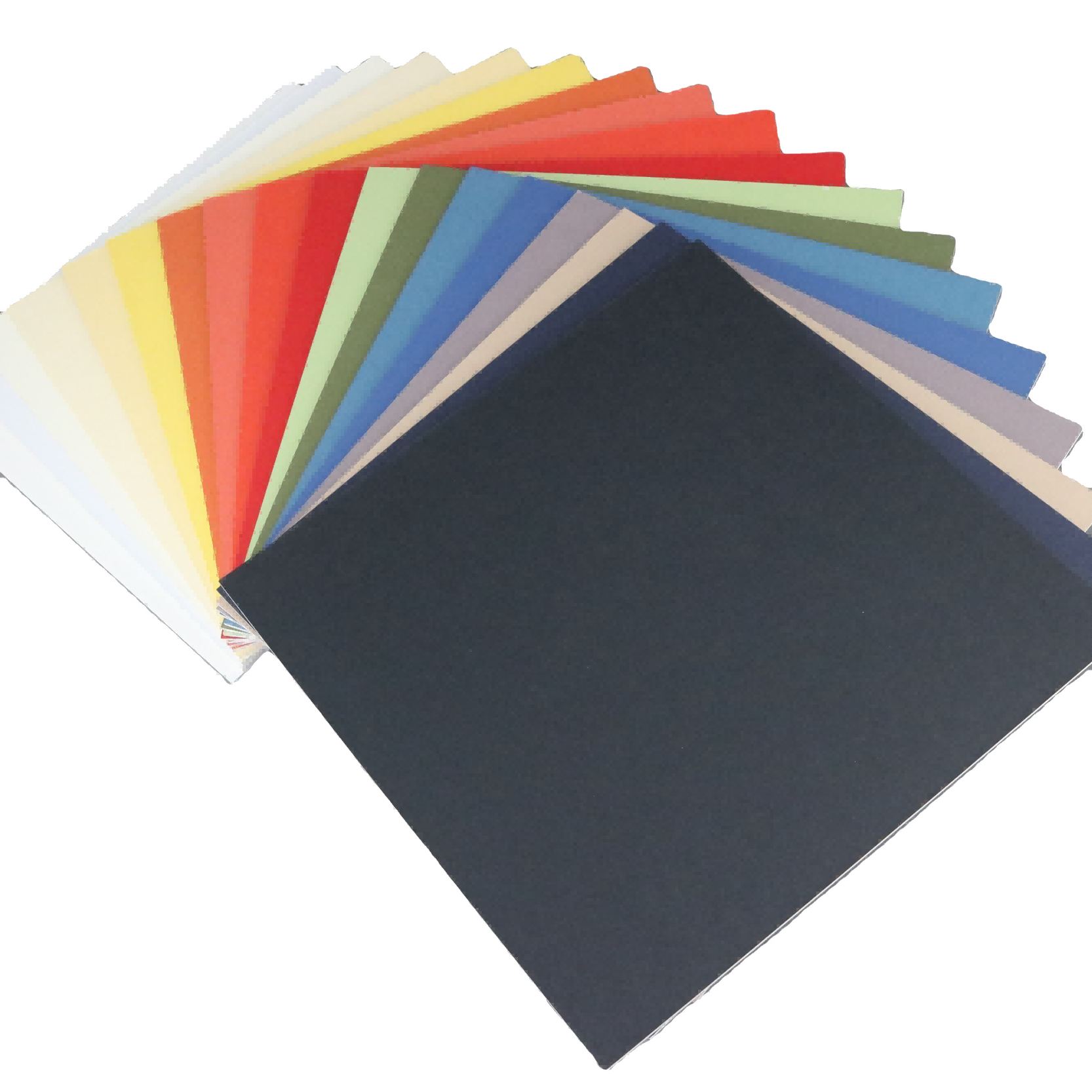

Color selection plays a significant role in commercial applications, where uncut mat board must be available in a wide range of colors and finishes to meet diverse customer preferences. The material's ability to maintain color consistency across different production batches ensures uniformity in large projects or repeat orders. Additionally, commercial framers require uncut mat board that processes cleanly without excessive dust generation, maintaining clean work environments and reducing cleanup requirements during high-volume production periods.

Proper Storage and Handling Techniques

Environmental Control and Storage Conditions

Proper storage of uncut mat board requires careful attention to environmental conditions that can affect the material's performance and longevity. Temperature control is essential, with ideal storage conditions maintaining a consistent range between 65-70°F to prevent expansion and contraction that could cause warping or dimensional changes. Humidity levels should be maintained between 45-55% relative humidity, as excessive moisture can lead to mold growth or chemical breakdown, while overly dry conditions may cause brittleness and cracking. Air circulation systems should provide adequate ventilation without creating direct drafts that could cause rapid moisture fluctuations.

Storage area cleanliness is crucial for maintaining the pristine condition of uncut mat board surfaces, requiring regular cleaning to prevent dust accumulation and contamination. Light exposure should be minimized during storage, as prolonged UV exposure can cause color fading or chemical degradation even before the material is used in framing applications. Proper shelving systems must provide adequate support across the entire surface area of stored sheets, preventing sagging or bending that could create permanent deformation in the material.

Handling Procedures and Contamination Prevention

Professional handling procedures for uncut mat board begin with proper personal preparation, including clean hands or appropriate gloves to prevent oil transfer or surface contamination. The material should be lifted and moved using both hands with support distributed evenly to prevent bending or stress concentration in specific areas. When removing sheets from storage stacks, careful sliding techniques prevent surface abrasion or edge damage that could compromise cutting operations or finished appearance.

Contamination prevention extends beyond physical handling to include protection from airborne pollutants, chemical vapors, and dust accumulation during processing and storage. Work surfaces must be clean and free from residual adhesives, cutting oils, or other substances that could transfer to the uncut mat board surface. Transportation procedures should include protective covering or wrapping to maintain surface integrity during movement between storage areas and work stations, ensuring that the material arrives at the cutting stage in optimal condition.

Cutting Techniques and Quality Control

Professional Cutting Equipment and Setup

Achieving professional results with uncut mat board requires appropriate cutting equipment that maintains blade sharpness and cutting accuracy throughout production runs. Mat cutting systems should be regularly calibrated to ensure precise measurements and consistent bevel angles that meet professional standards. Blade selection becomes critical when working with different grades of uncut mat board, as varying densities and compositions may require specific cutting edge geometries for optimal results. Regular blade replacement schedules prevent edge quality degradation that can compromise the appearance of finished mats.

Cutting surface preparation involves ensuring that the base material provides adequate support without causing blade damage or cutting irregularities. The work environment should be well-lit and dust-free to prevent contamination during the cutting process and to enable accurate visual inspection of cut edges. Tool maintenance procedures must include regular cleaning and lubrication of cutting mechanisms to ensure smooth operation and consistent performance across different types of uncut mat board materials.

Quality Assessment and Edge Finishing

Quality control procedures for cut uncut mat board involve systematic inspection of edge characteristics, including smoothness, bevel angle consistency, and freedom from chips or tears. Professional standards require clean, precise cuts that maintain their appearance over time without developing frayed edges or other defects that could detract from the finished presentation. Color consistency across cut edges becomes particularly important when working with colored mat board, ensuring that the beveled surfaces complement rather than contrast with the face color.

Edge finishing techniques may include light sanding or burnishing to achieve optimal smoothness, particularly when working with textured or heavily pigmented uncut mat board variants. Surface cleaning procedures remove any cutting debris or residual particles that could interfere with assembly operations or migrate to artwork surfaces. Final inspection protocols verify that all dimensional specifications are met and that the cut pieces maintain the archival properties of the original uncut mat board material.

Integration with Framing Systems

Compatibility with Glazing Materials

The integration of uncut mat board with various glazing materials requires careful consideration of thermal expansion characteristics and chemical compatibility to ensure long-term stability in framing assemblies. Different glazing options, including standard glass, UV-filtering glass, and acrylic alternatives, each present unique interaction possibilities with mat board materials. The spacing created by the mat board thickness must be sufficient to prevent contact between artwork and glazing while maintaining structural integrity within the frame assembly. Thermal cycling considerations become important in environments with significant temperature variations, requiring mat board materials that maintain dimensional stability across expected temperature ranges.

Chemical interactions between uncut mat board and glazing materials must be evaluated to prevent degradation or staining that could develop over time. Outgassing from certain glazing materials or sealants could potentially interact with mat board components, requiring selection of compatible material combinations. The edge sealing characteristics of the mat board assembly affect internal humidity control within the framing package, influencing the overall preservation environment for the enclosed artwork.

Assembly Techniques and Structural Considerations

Professional assembly techniques for incorporating uncut mat board into framing systems require attention to material stacking order and attachment methods that maintain archival integrity. The positioning of the mat board within the frame stack affects air circulation patterns and moisture control, influencing the internal environment that surrounds the artwork. Fastening methods must be reversible and non-damaging to both the mat board and adjacent materials, allowing for future conservation work if required.

Structural loading considerations include evaluating how the weight of the artwork and framing components affects the mat board over time, particularly in large format installations. The material's compression resistance and recovery characteristics determine its ability to maintain consistent spacing and support throughout the frame's service life. Expansion joint considerations may be necessary in large installations where thermal movement could stress the mat board material beyond its elastic limits.

FAQ

What thickness of uncut mat board is best for standard artwork framing

Standard artwork framing typically utilizes uncut mat board with 4-ply thickness, which measures approximately 1/16 inch or 1.4mm. This thickness provides adequate spacing between artwork and glazing while maintaining structural stability for most applications. Heavier artworks or pieces requiring greater separation may benefit from 6-ply or 8-ply options, which offer increased thickness and enhanced structural support. The selection should consider both the artwork's weight and the desired visual proportion between the mat border and the framed piece.

How can I verify that uncut mat board meets archival standards

Archival quality uncut mat board should be labeled as acid-free and lignin-free, with pH levels between 7.5 and 8.5. Look for materials that have passed the Photographic Activity Test (PAT) and comply with ANSI/NISO Z39.48 standards for permanent paper. Reputable manufacturers provide documentation certifying these characteristics, and professional-grade products often include specific test results and compliance certifications. When in doubt, request technical data sheets that detail the material's composition and testing results.

What are the signs that uncut mat board has deteriorated and needs replacement

Deterioration signs in uncut mat board include color changes such as yellowing or browning, particularly around edges or areas of stress. Surface texture changes, including brittleness, flaking, or powdering, indicate chemical breakdown that compromises archival properties. Warping or dimensional changes suggest moisture damage or environmental stress that affects the material's performance. Any visible staining, foxing, or discoloration that wasn't present originally indicates chemical deterioration that could affect adjacent artwork materials.

Can uncut mat board be recycled or disposed of safely after use

High-quality uncut mat board made from cotton fibers can typically be recycled with other paper products, though local recycling programs may have specific requirements. Acid-free, lignin-free materials are generally safe for standard disposal methods and don't pose environmental hazards when sent to landfills. However, mat board that has been contaminated with adhesives, mounting materials, or other chemicals may require special disposal consideration. Check with local waste management authorities for specific guidance on disposing of framing materials in your area.