pre cut mat board sizes

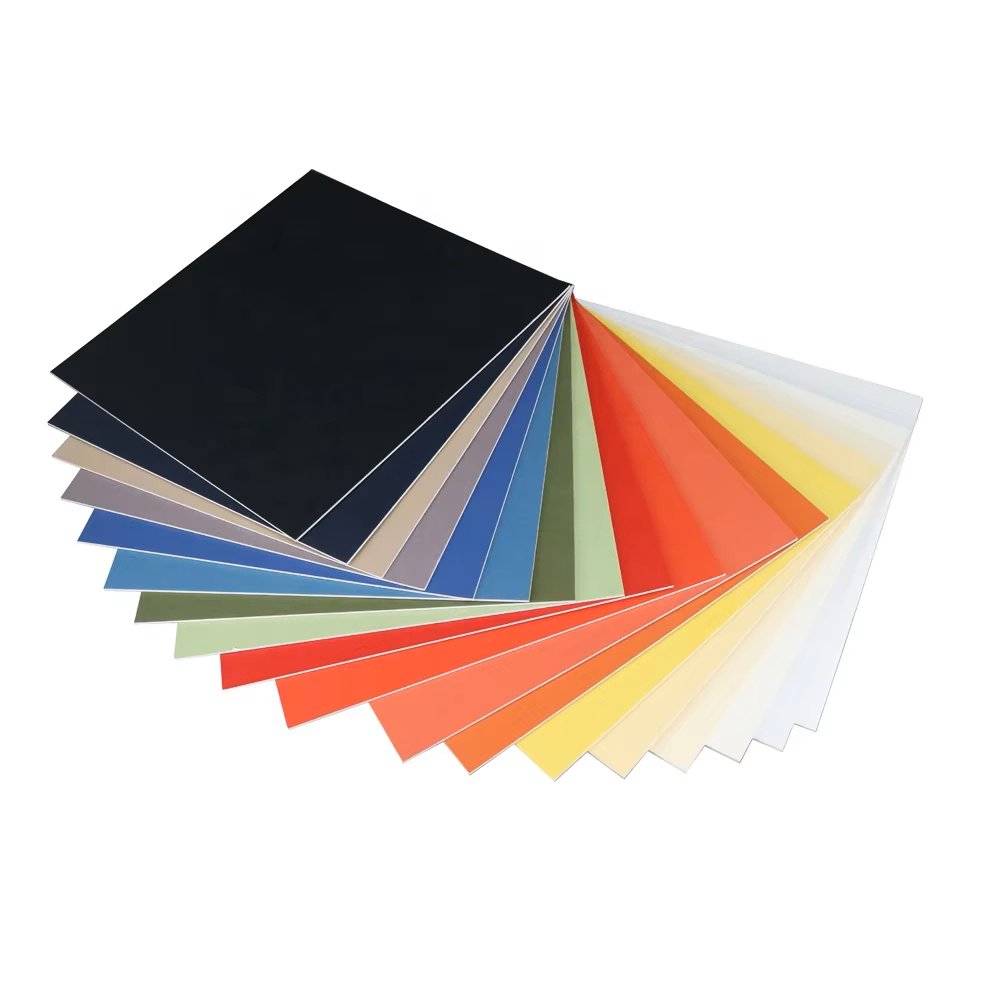

Pre cut mat board sizes represent a fundamental component in the framing and presentation industry, offering standardized dimensions that cater to various artistic and display needs. These professionally prepared boards come in an extensive range of standard sizes, typically matching common photo and artwork dimensions, from 5x7 inches up to 32x40 inches. The boards are precision-cut using advanced machinery to ensure perfectly straight edges and precise right angles, eliminating the need for manual cutting and reducing waste. Manufactured from high-quality, acid-free materials, these mat boards provide essential protection for artwork while enhancing its visual presentation through carefully calculated borders. The core technology involves multi-layer construction, featuring a solid core sandwiched between surface papers, creating a clean, beveled edge when cut. Modern pre cut mat boards often incorporate conservation-grade materials that protect artwork from acid degradation and UV damage, making them ideal for both temporary displays and long-term preservation projects. These boards serve multiple applications across various sectors, from professional framing shops to educational institutions, galleries, and home DIY projects, providing consistent quality and professional results without requiring specialized cutting equipment.