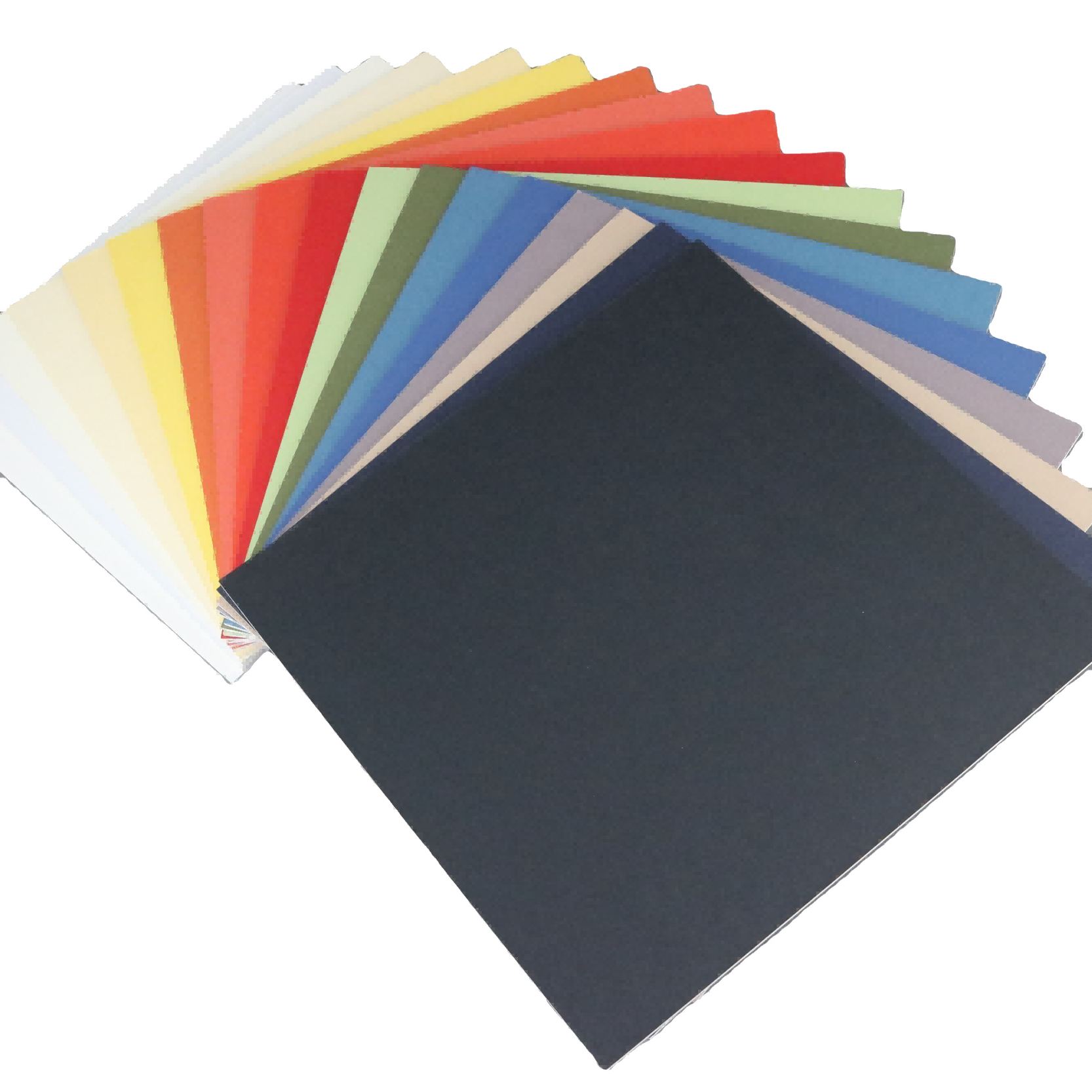

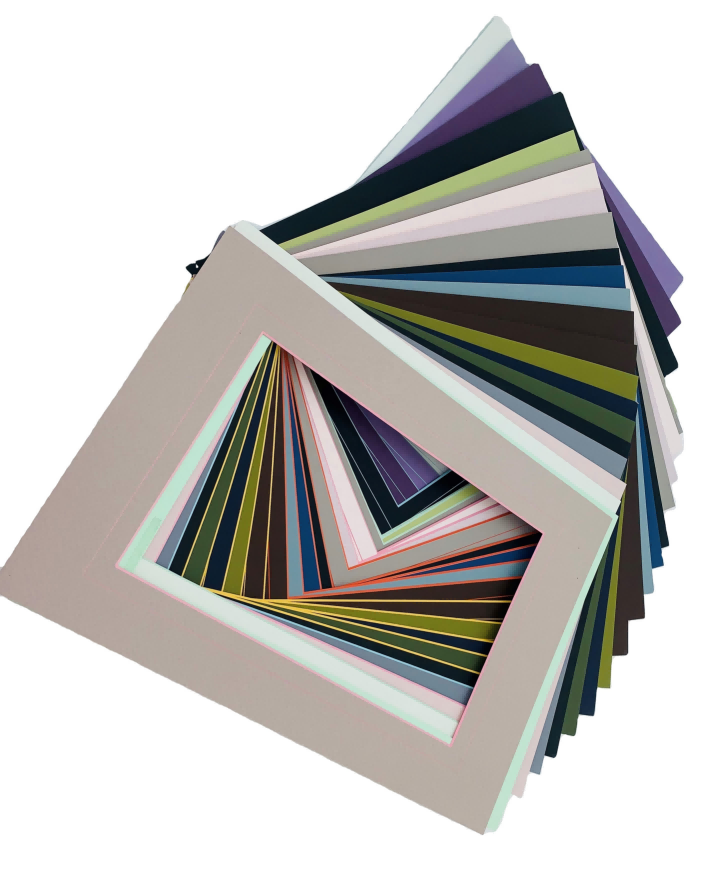

picture frame matboard manufacturer

A picture frame matboard manufacturer represents a sophisticated production facility dedicated to creating high-quality matboards essential for professional framing applications. These advanced manufacturing systems integrate precision cutting technology, automated material handling, and quality control processes to produce matboards that meet exact specifications. The facility typically features state-of-the-art computerized cutting machines capable of executing intricate designs and multiple opening configurations with exceptional accuracy. The manufacturing process begins with the selection of premium conservation-grade materials, which are then processed through automated systems that maintain consistent quality and dimensional accuracy. Modern matboard manufacturers incorporate advanced color matching technology to ensure precise color reproduction and consistency across production runs. The facility's production line includes specialized equipment for beveling, which creates the characteristic angled cuts that define professional matting. Environmental controls within the manufacturing space maintain optimal temperature and humidity levels to prevent material warping and ensure dimensional stability. Quality assurance stations throughout the production process utilize digital imaging and measurement systems to verify specifications and maintain exceptional standards. The manufacturer's capabilities extend to custom sizing, specialty finishes, and archival-quality materials, serving the diverse needs of professional framers, galleries, museums, and high-end retail framing operations.