passepartout manufacturer

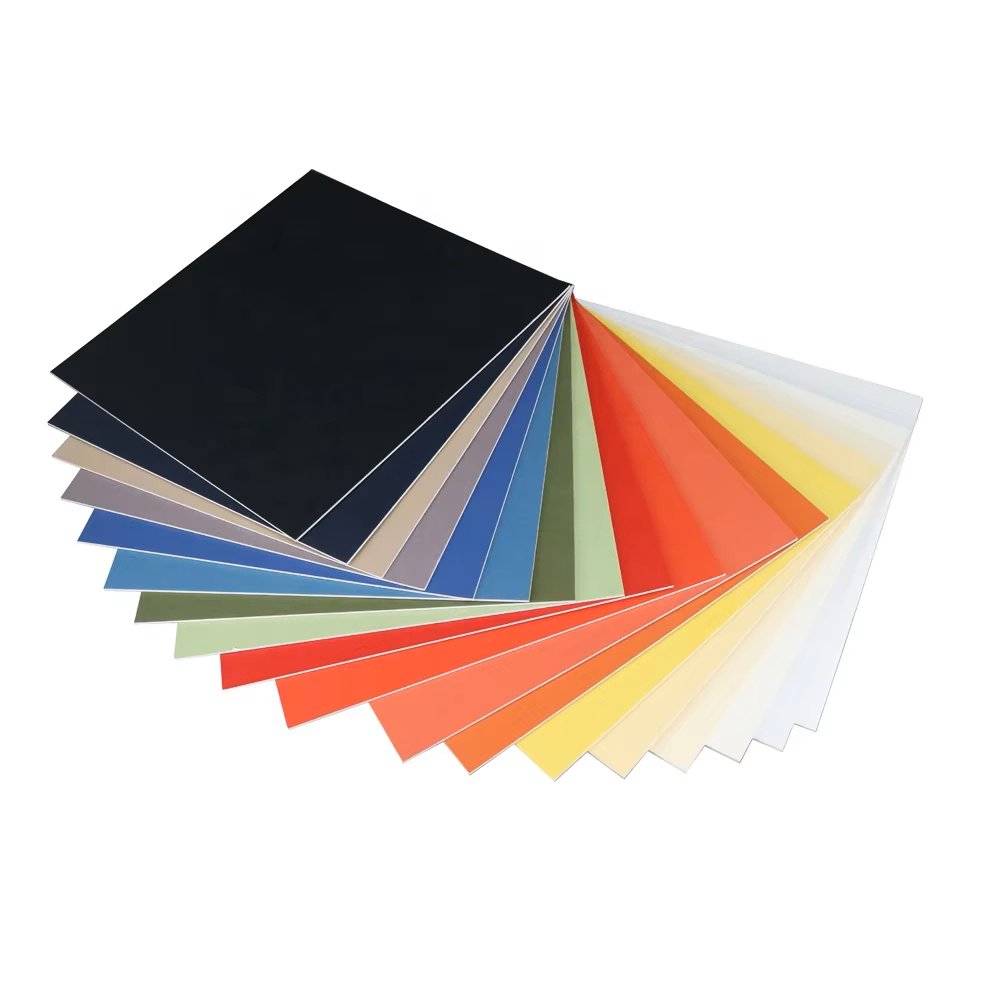

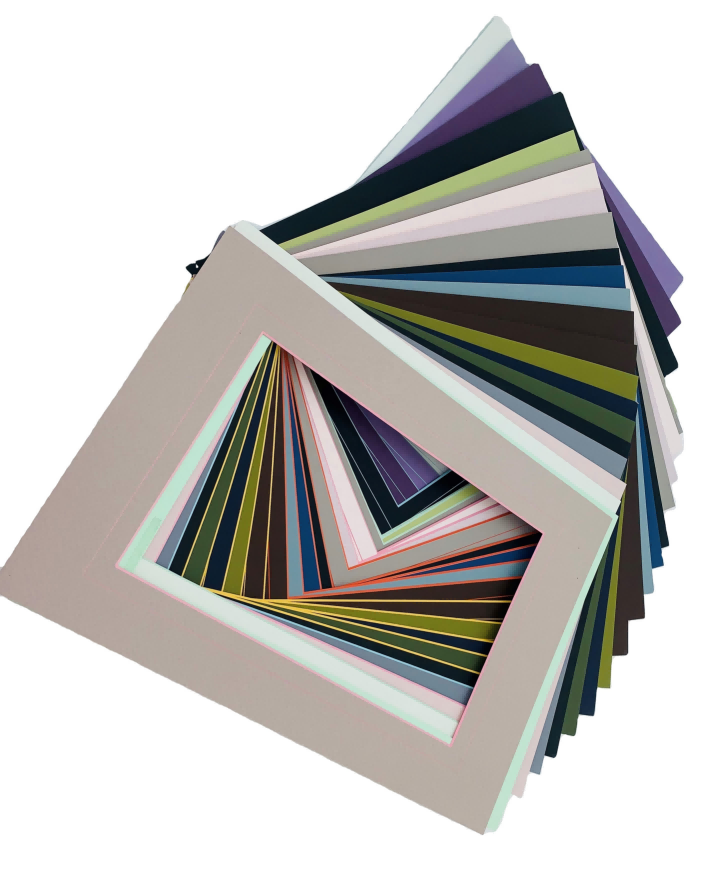

A passepartout manufacturer represents a cutting-edge solution in the framing industry, specializing in the production of high-quality mat boards that enhance artwork presentation. These sophisticated machines combine precision engineering with automated technology to create perfectly cut window mats with consistent quality and professional finishes. The system employs advanced cutting mechanisms that can handle various mat board materials, from standard to conservation-grade boards, ensuring versatility in applications. Modern passepartout manufacturers feature digital control systems that allow for intricate designs, multiple openings, and custom shapes, enabling frame shops to meet diverse customer requirements efficiently. The equipment typically includes automated measuring systems, precision cutting heads, and user-friendly interfaces that streamline the production process. With capabilities ranging from basic rectangular cuts to complex decorative patterns, these machines can accommodate projects of varying sizes and complexities. The technology incorporates safety features and dust collection systems, maintaining a clean working environment while protecting operators. These manufacturers have revolutionized the framing industry by reducing manual labor, minimizing material waste, and ensuring consistency in production quality.