paper photo frame manufacturer

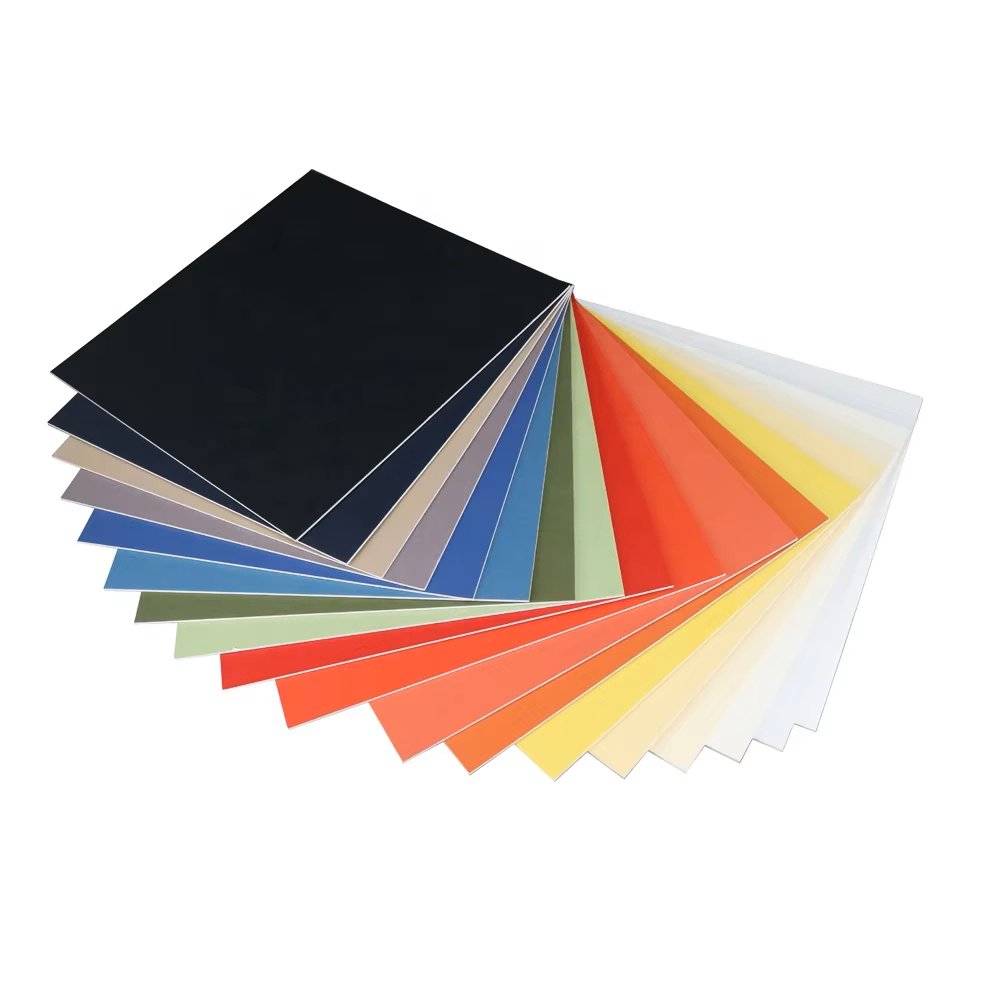

A paper photo frame manufacturer represents a specialized facility dedicated to producing high-quality, customizable photo frames using various paper materials. These manufacturers employ advanced production techniques, combining traditional craftsmanship with modern automation to create durable, aesthetically pleasing frames. The manufacturing process typically involves precision cutting equipment, specialized folding machinery, and quality control systems that ensure consistent product standards. These facilities can produce frames in various sizes, styles, and designs, from simple single-photo displays to elaborate multi-photo arrangements. The manufacturing process incorporates eco-friendly materials and sustainable practices, utilizing recycled paper products and environmentally conscious production methods. Modern paper photo frame manufacturers integrate digital design capabilities, allowing for customized printing, embossing, and unique surface treatments that enhance the final product's appeal. They maintain strict quality control measures throughout the production cycle, from raw material selection to final packaging, ensuring each frame meets specific durability and appearance standards. The facilities often feature automated assembly lines combined with manual quality inspection points, guaranteeing both efficiency and attention to detail in the final product.