matboard manufacturer

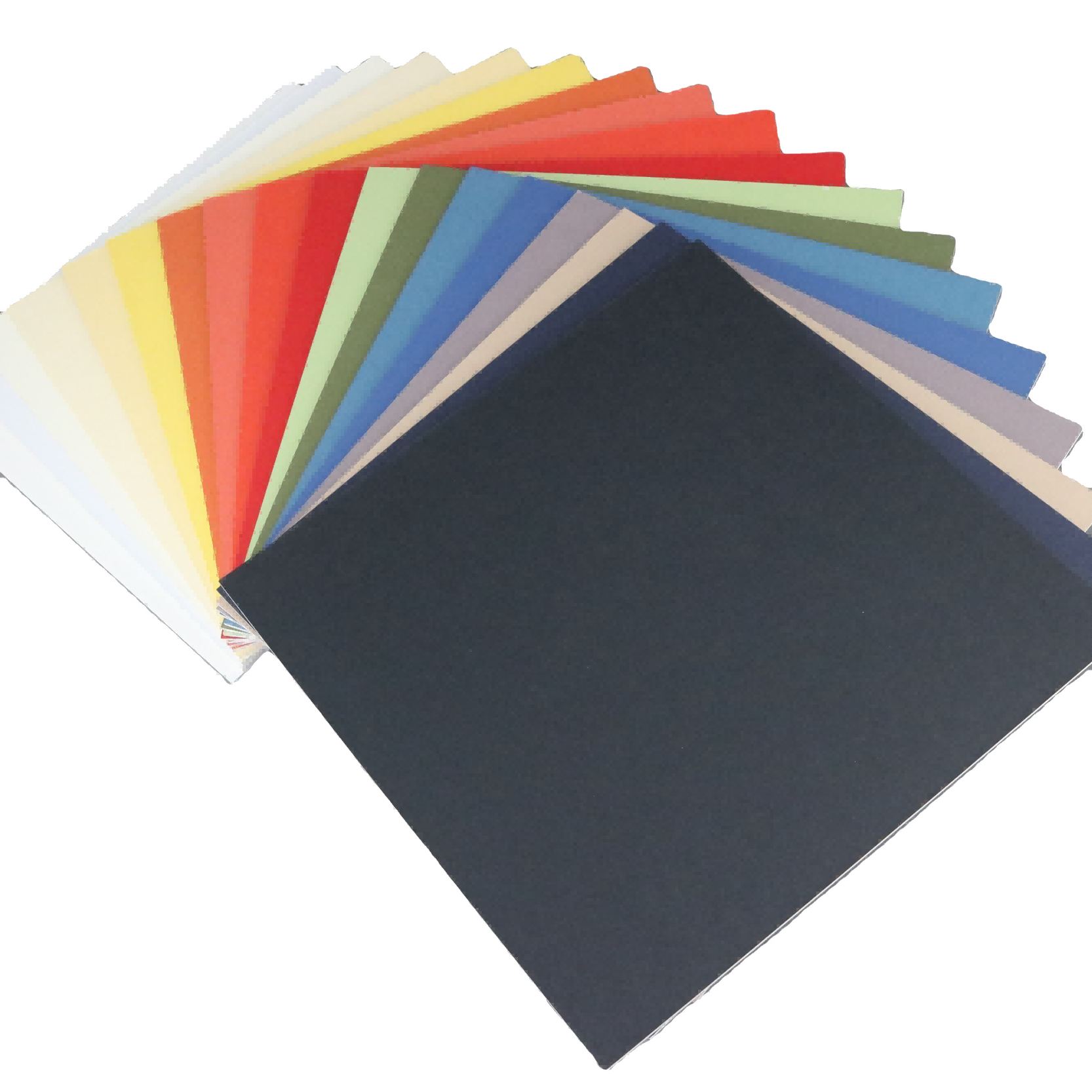

A matboard manufacturer represents a sophisticated industrial solution designed to produce high-quality matboards essential for framing, packaging, and artistic presentations. These advanced systems integrate cutting-edge technology with precision engineering to deliver consistent, professional-grade results. The manufacturer incorporates automated cutting mechanisms, digital measurement systems, and intelligent material handling capabilities to process various board materials efficiently. Operating through a computer-controlled interface, it enables operators to program exact specifications for multiple mat cuts, ensuring accuracy to fractions of a millimeter. The system's versatility allows for processing different thicknesses and types of matboard materials, from standard archival boards to specialty decorative options. Advanced features include automatic waste removal, integrated storage solutions, and rapid production capabilities that can handle high-volume orders while maintaining exceptional quality standards. The manufacturer's sophisticated software interface allows for complex designs, including multiple openings, decorative edges, and custom patterns, making it invaluable for professional framing operations, museums, and high-end art galleries. Safety features such as automatic shut-offs, debris collection systems, and ergonomic design ensure operator protection while maintaining optimal productivity.