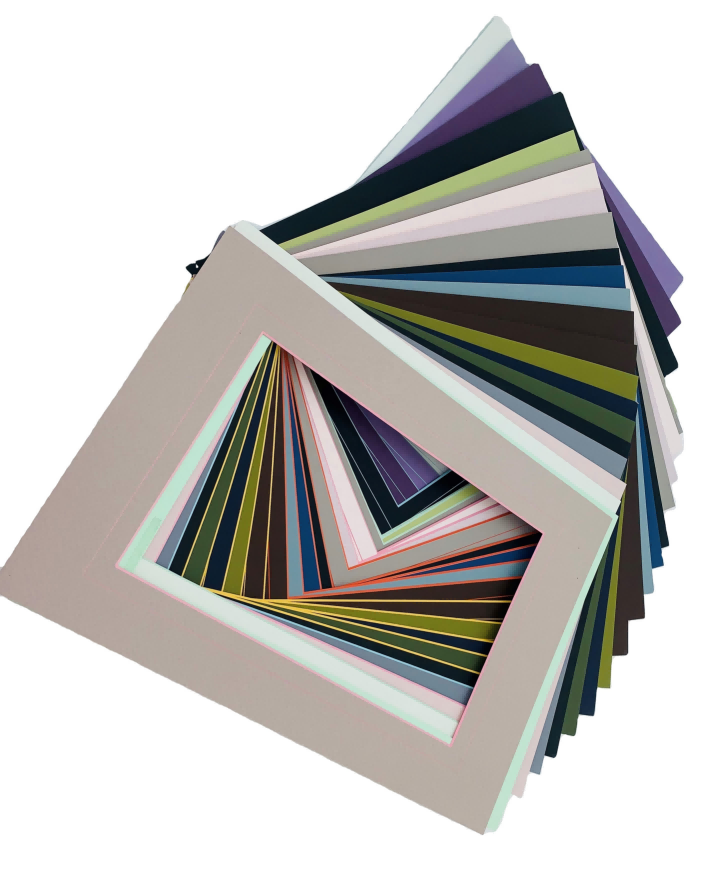

custom cut matboards

Custom cut matboards represent a professional framing solution that enhances and protects artwork while adding depth and sophistication to any display. These precisely cut boards are manufactured using high-quality, acid-free materials that ensure long-term preservation of valuable artwork. The cutting process employs advanced computerized technology to achieve precise measurements and clean, beveled edges at exactly 45-degree angles. These matboards come in various thicknesses, typically ranging from 2-ply to 8-ply, allowing for different dimensional effects. Available in hundreds of colors and textures, custom cut matboards can be designed to complement any artwork or interior decor scheme. They serve multiple purposes: creating a visual buffer between the artwork and glass, preventing artwork from touching the glazing, and adding professional presentation value. The technology behind custom cut matboards allows for intricate designs, including multiple openings, decorative corners, and unique shapes that can enhance the overall aesthetic appeal of framed pieces. These matboards are particularly valuable for conservation framing, as they provide essential spacing and protection while maintaining archival quality standards.