acid free board manufacturer

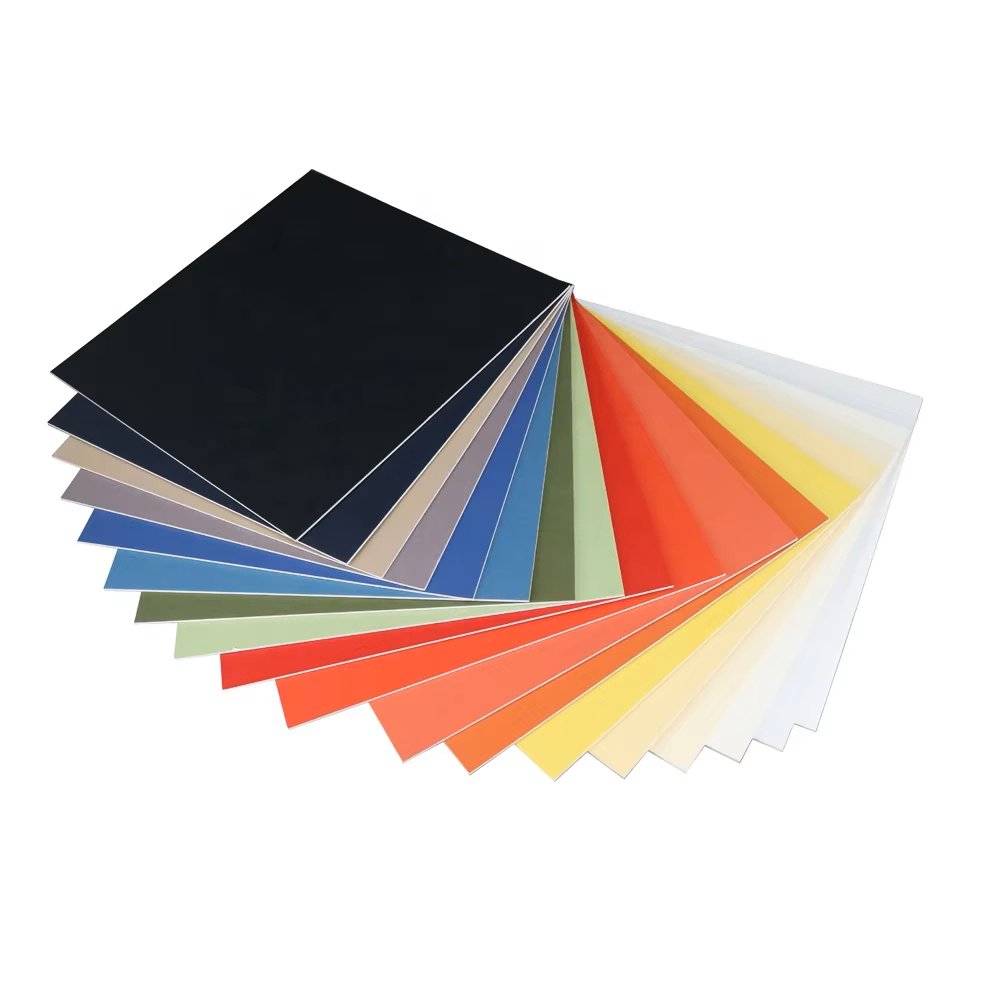

An acid free board manufacturer specializes in producing high quality conservation grade materials essential for preserving valuable documents, artwork, and artifacts. These specialized facilities employ advanced manufacturing processes that ensure their boards maintain a neutral pH level, typically between 7 and 8.5, preventing deterioration caused by acidic compounds. The manufacturing process involves carefully selected raw materials, including pure cellulose fibers and alkaline buffers, processed through state of the art equipment that maintains strict quality control standards. Modern acid free board manufacturers utilize sophisticated testing methods to verify pH levels, lignin content, and overall material stability. Their production lines are equipped with precision cutting tools, environmental control systems, and automated quality inspection stations to ensure consistent product quality. These facilities often maintain climate controlled environments throughout the manufacturing process, as temperature and humidity can significantly impact the final product's properties. The manufacturer's capabilities typically include producing various board thicknesses, sizes, and surface finishes to meet diverse preservation needs. Additionally, many manufacturers offer customization options, including different colors, textures, and specialized coatings for specific applications. The resulting products serve critical roles in museums, archives, libraries, and professional framing establishments, where long term preservation is paramount.